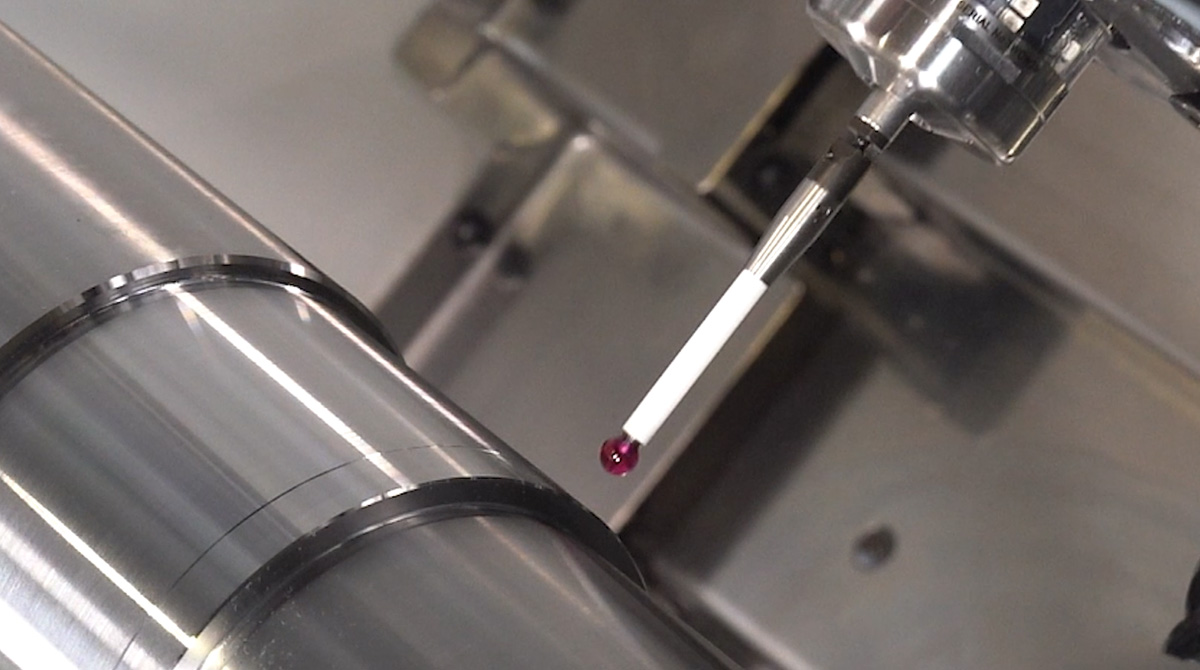

Measurements during the manufacturing process are required for long machining runs where tool wear must be corrected and compensated during the machining operations. It is also required in order to remove machine's thermal deviations that affect the part dimensionally or to achieve very tight tolerances.

The part is measured and then, the value is compared against the reference diameter established during calibration in order to modify tool offsets or the part origins. Measurements can also be used to determine and correct the part orientation for any machining operation.

This video was filmed with a high precision CNC lathe: TD-30-Y-1350

DISCOVER ALL THE PROGRAMMING TIPS WITH THIS FREE DOWNLOADABLE

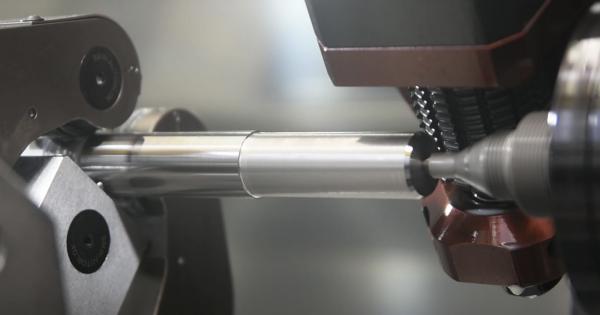

Polygon turning is a process through which flat planes are obtained on the piece through synchronized rotation of the spindle and the live tool. Polygon turning can be performed on our CMZ CNC lathes. It is an alternative process to milling each surface individually. It is more similar to lathing…

The geometry of the gear in the gear hobbing process is obtained by the synchronised movement between the spindle and the live tool. The limit to manufacture gears in a CMZ CNC lathe is around the hob tool being able to produce the required profile but for occasional machining. Bigger gears require…

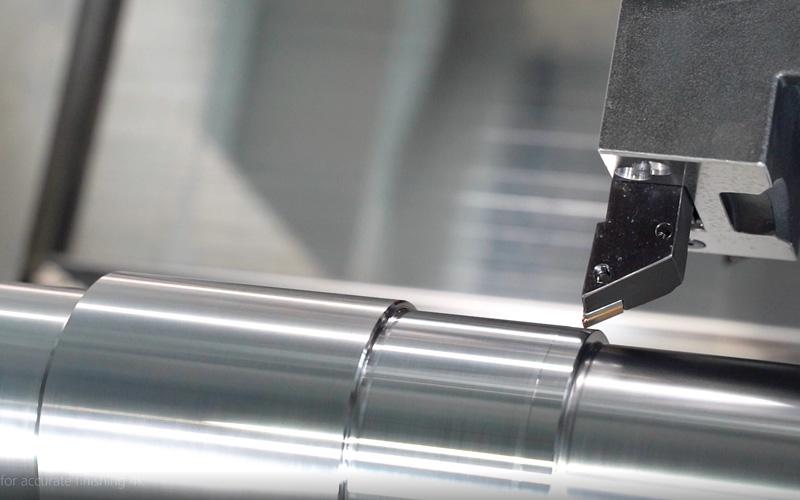

Thread rolling may be your solution. This process forms the thread by shaping the metal, without removing chips. This is done using rollers that are the "negative" of the thread being produced. The machining times are much shorter than for thread turning, since it is done in just one round. Furthermore, the…

Integrated motors on both turrets offer a combination of two 12-station turrets (24 live positions) and 14kW/42Nm driven tool power with spindle speeds of up to 12,000 rpm, a massive advantage for achieving quicker cycle times. Together with a generous Y-axis travel of +/-45mm available on both turrets,…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.