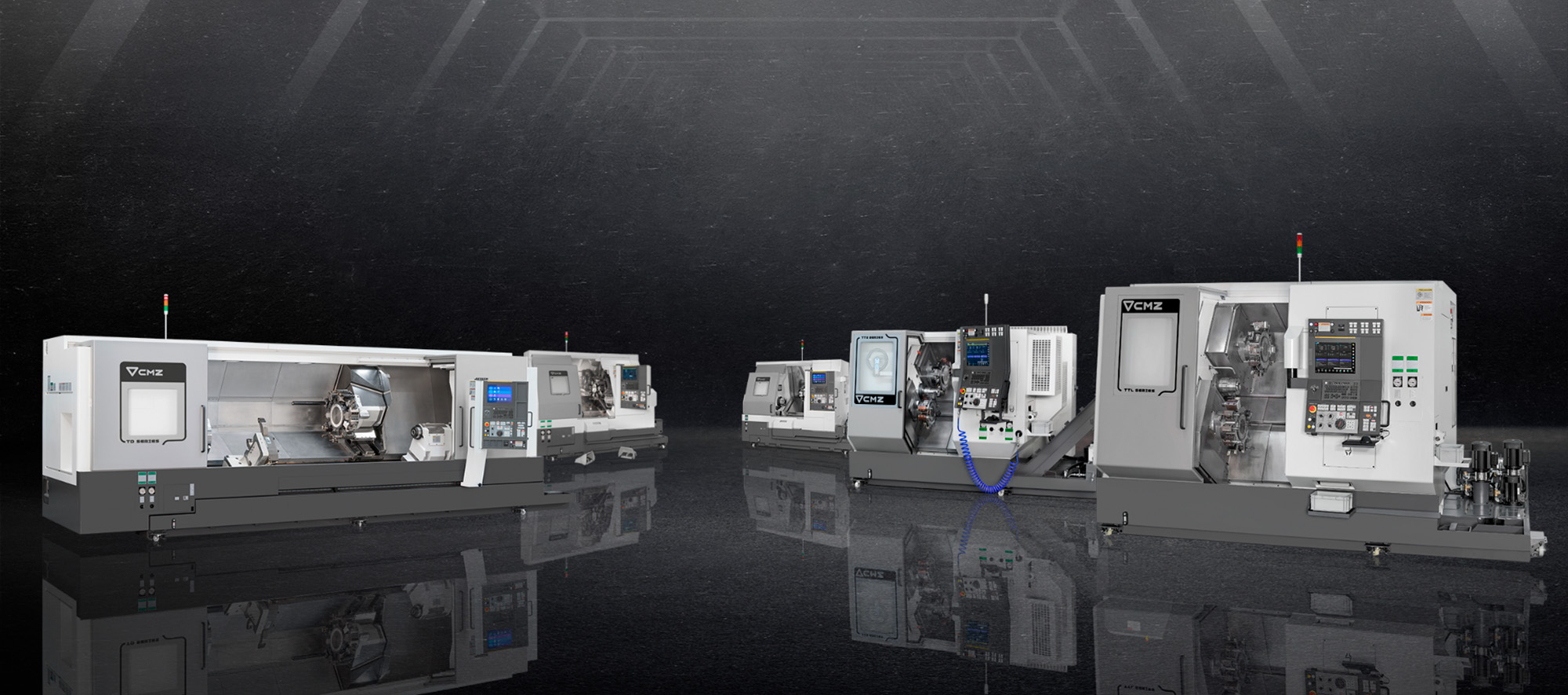

WE HAVE THE CNC LATHE YOU REQUIRE

TA SERIES

PRECISION AND RELIABILITY

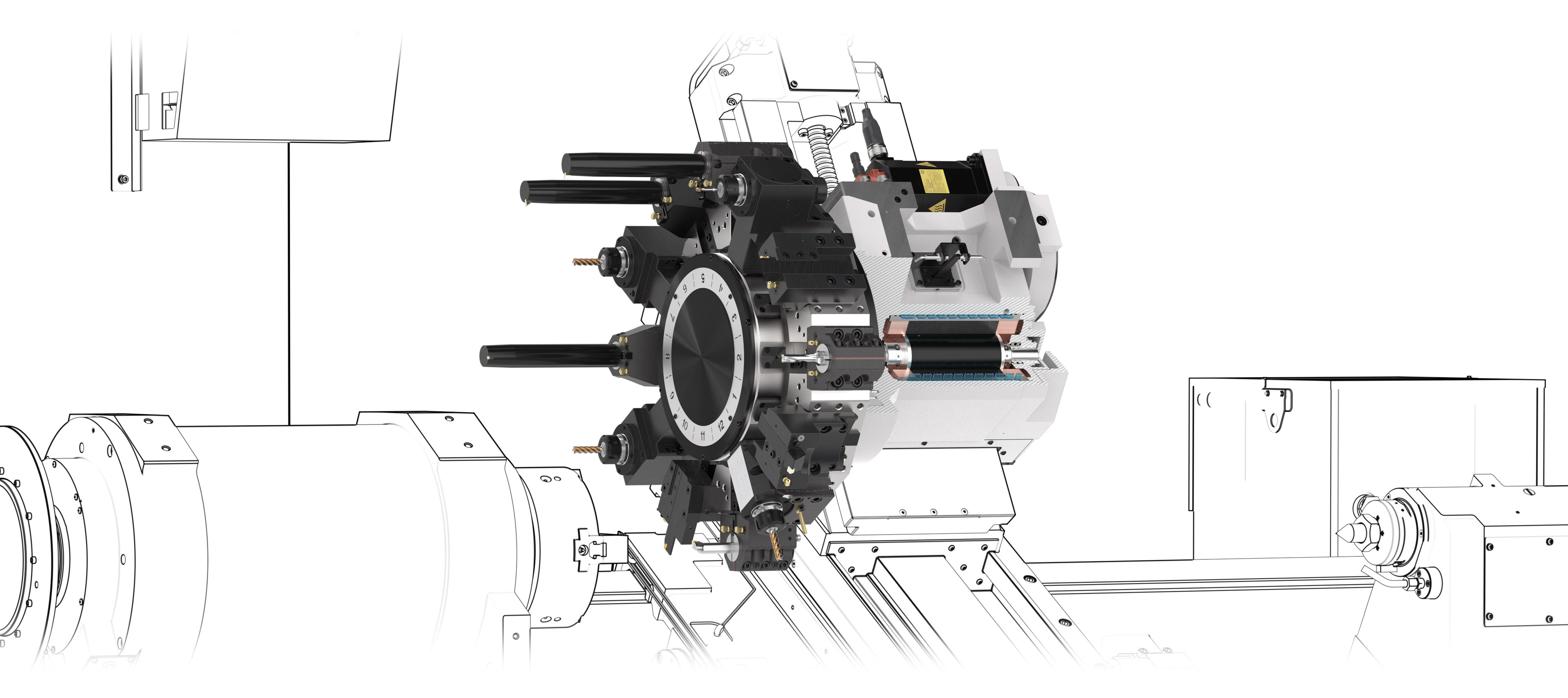

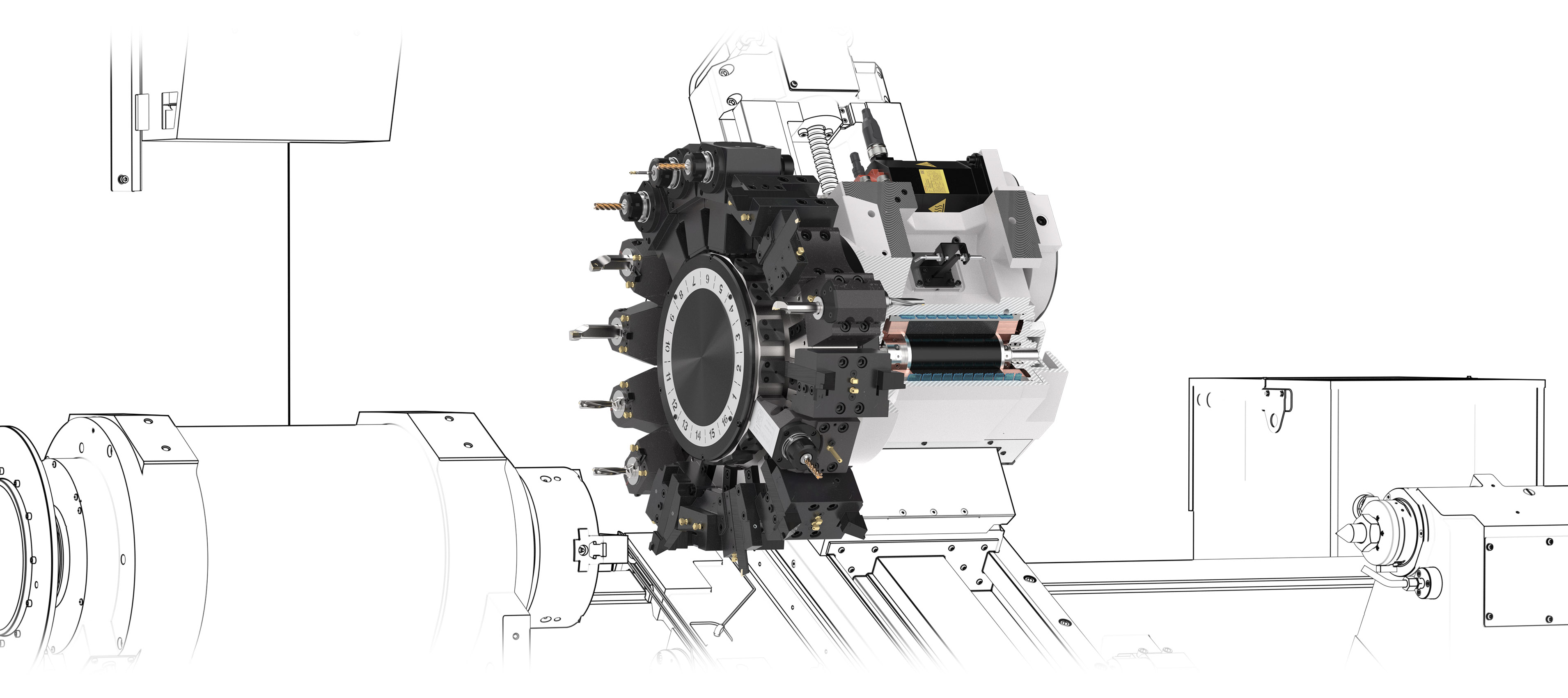

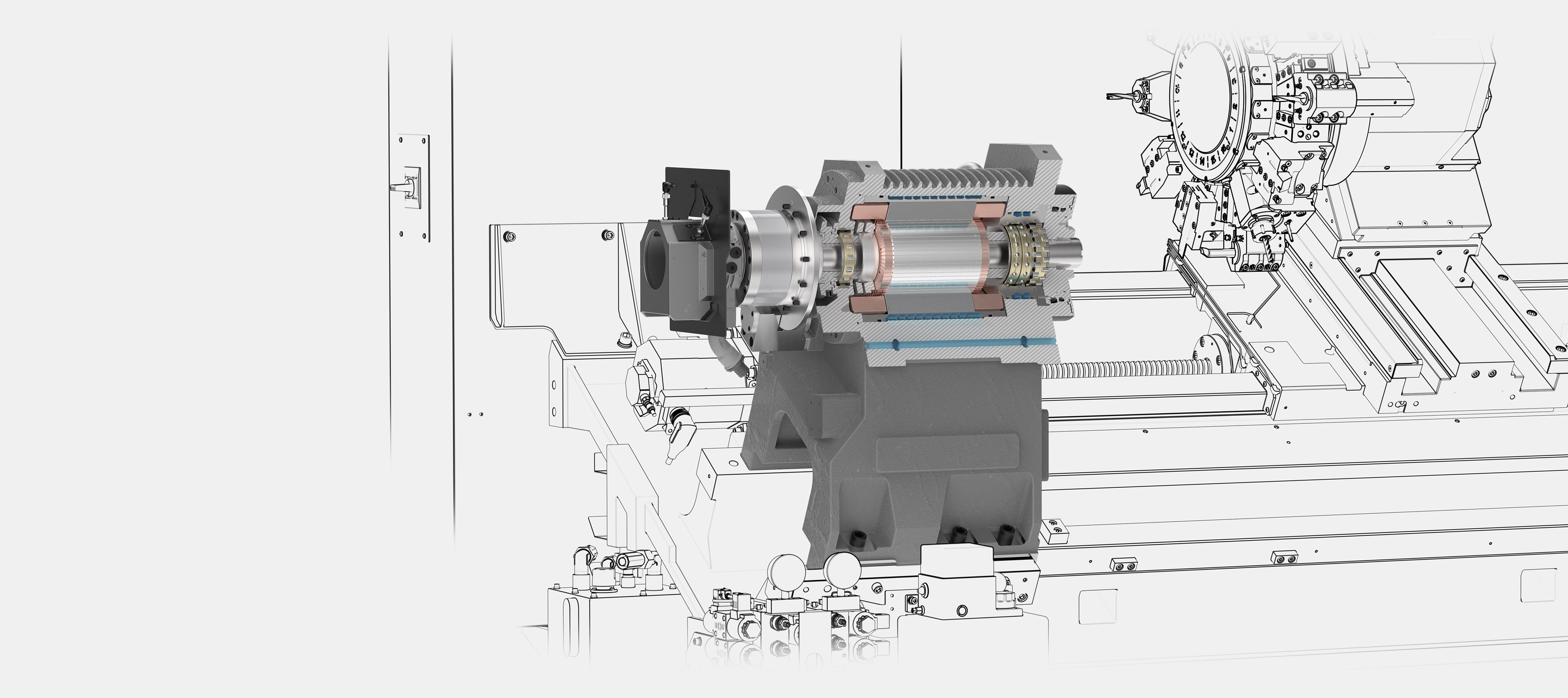

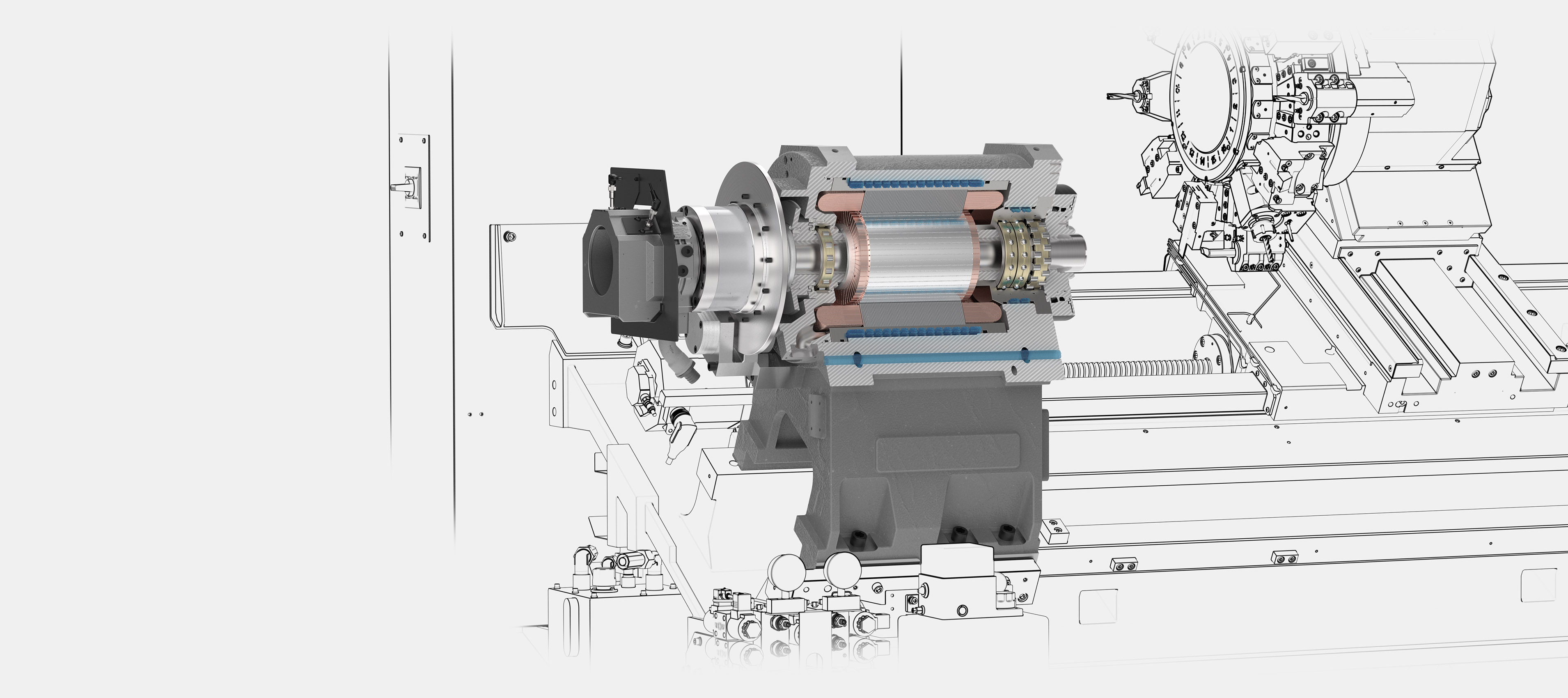

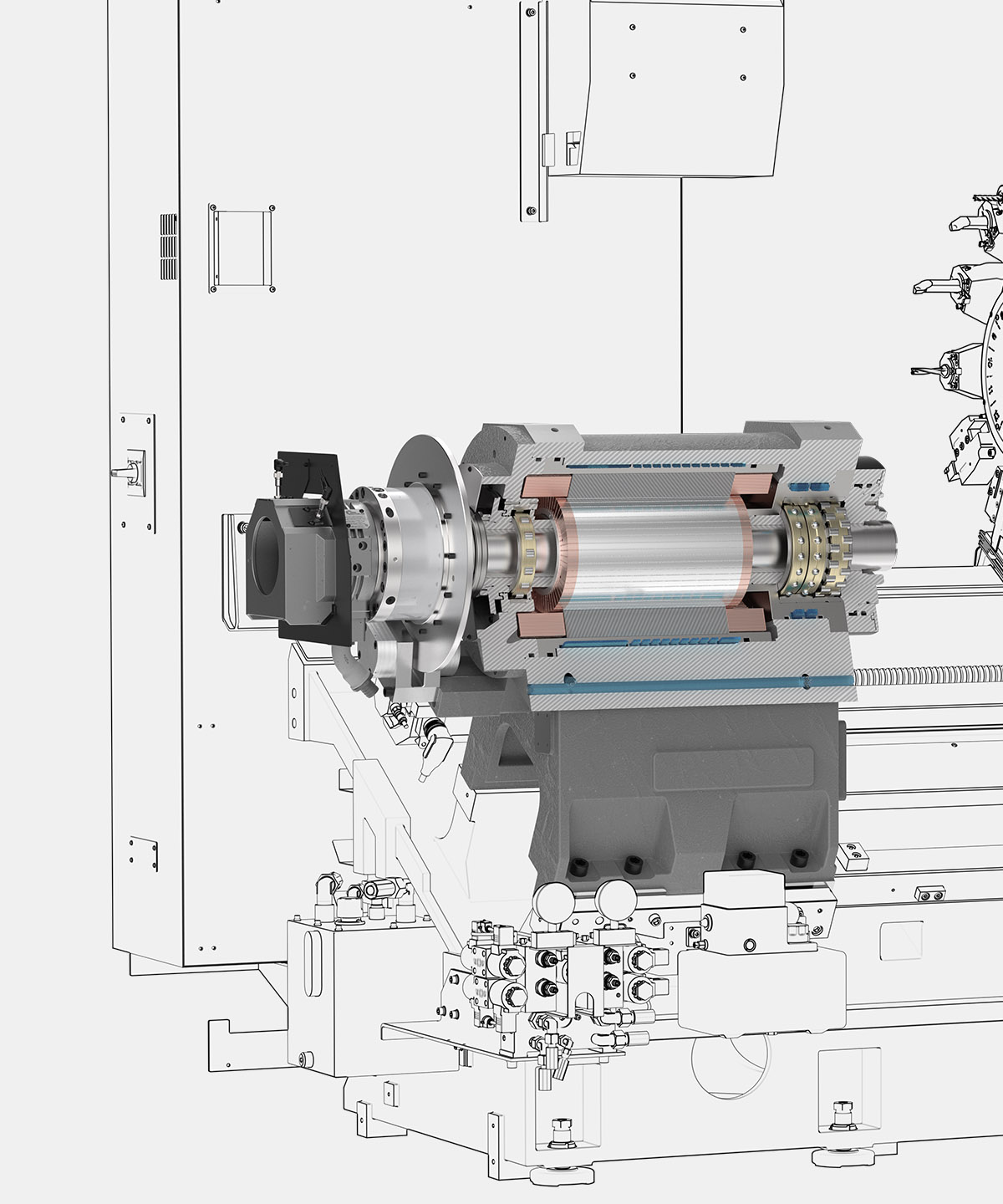

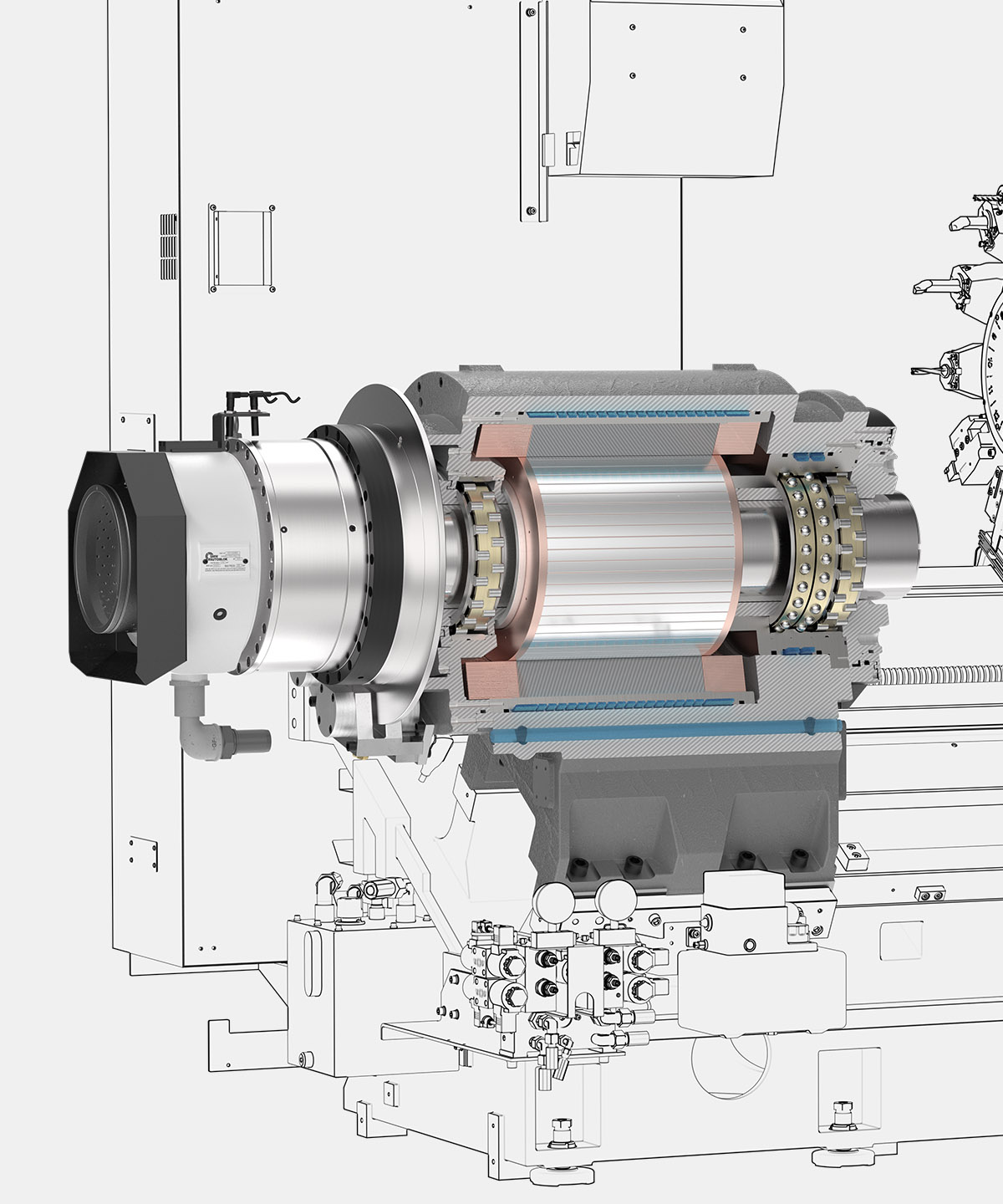

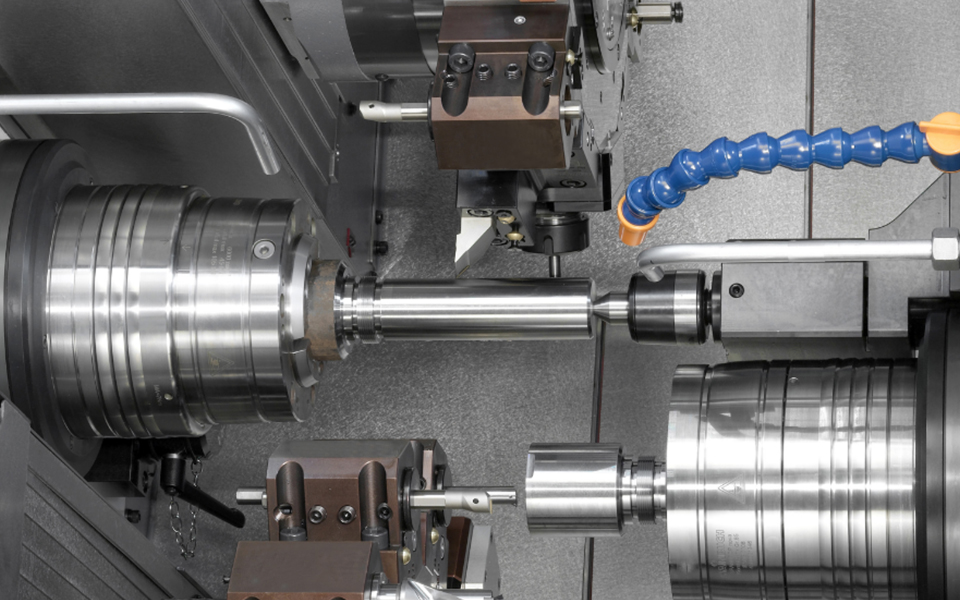

If you are looking for a CNC machine that’s high performance, powerful and reliable, our TA Series, the bestselling CNC machine in our range, is your best ally. We offer 3 bed lengths with multiple configuration options, which include a turret with an integrated fully oil-cooled 12,000rpm driven tool motor.

TD SERIES

Z800 – Z1350 | INCLINED BED

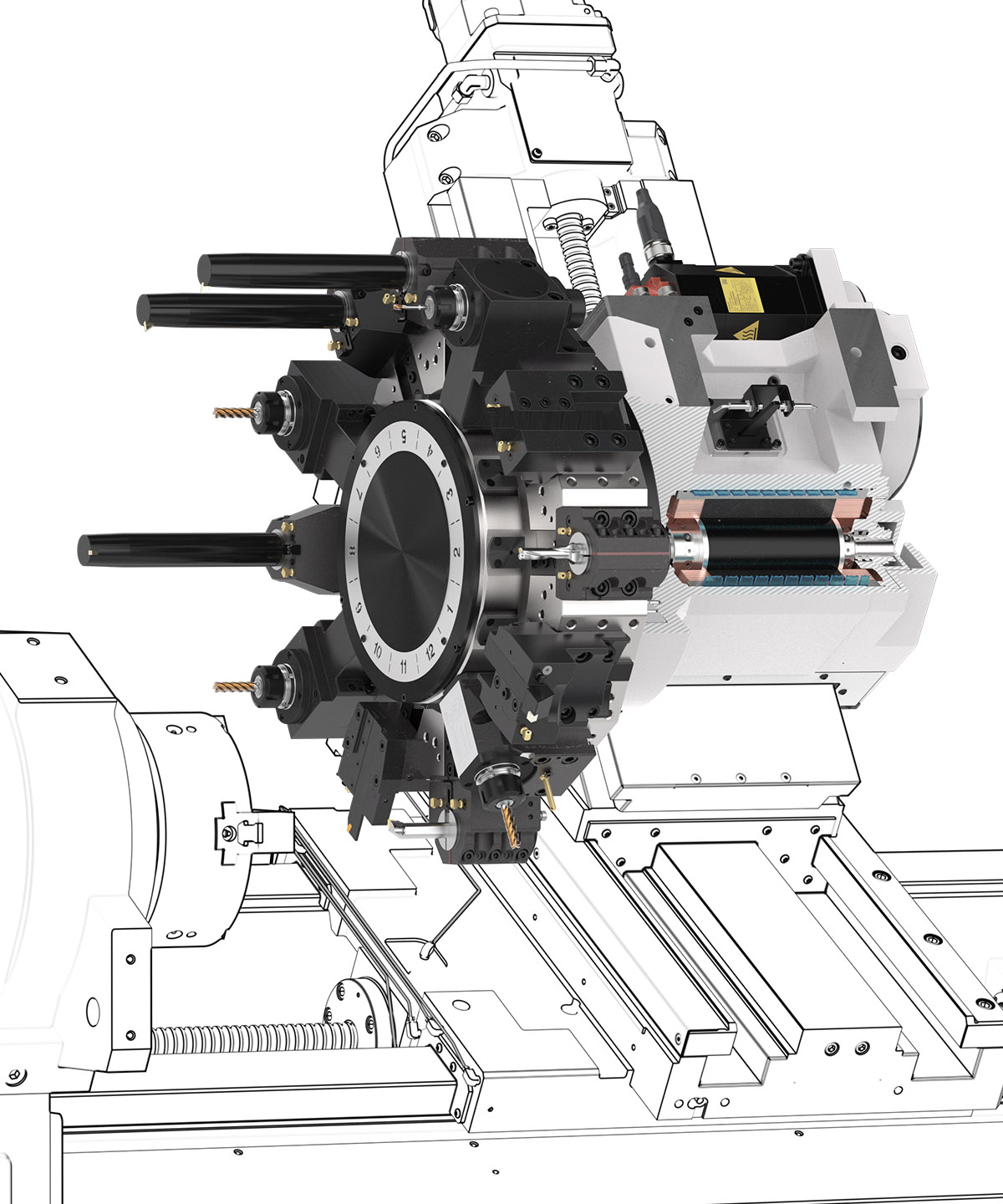

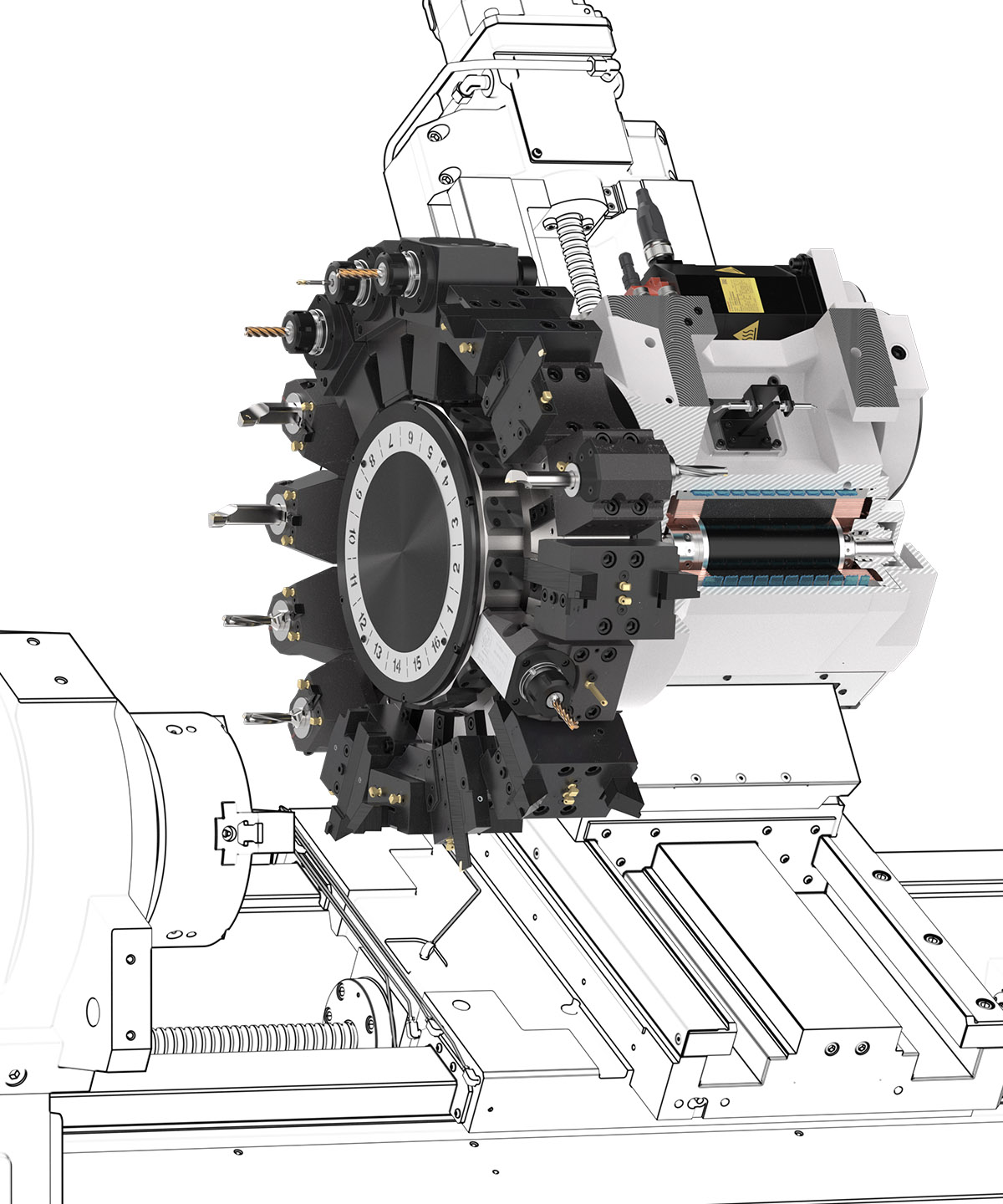

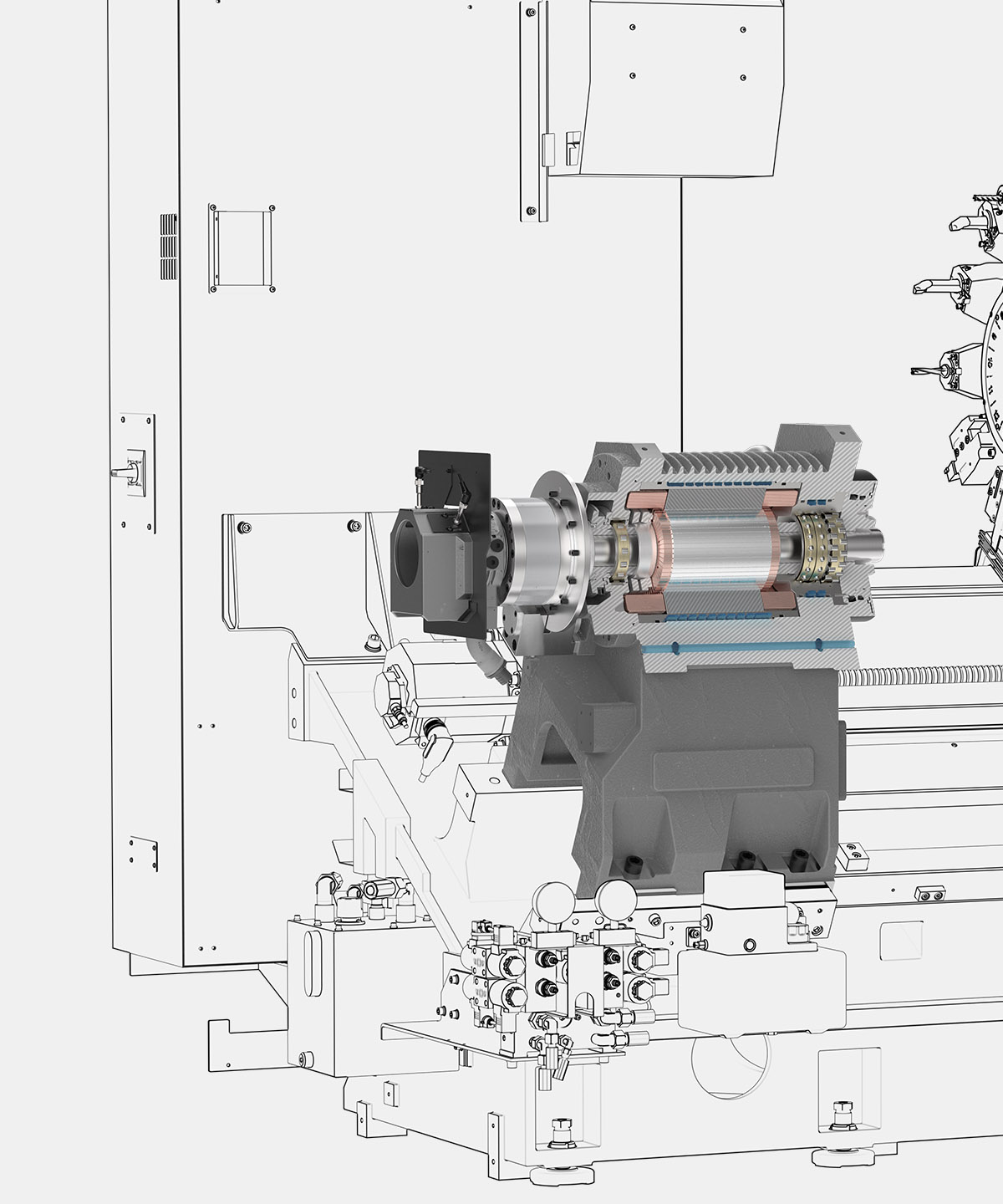

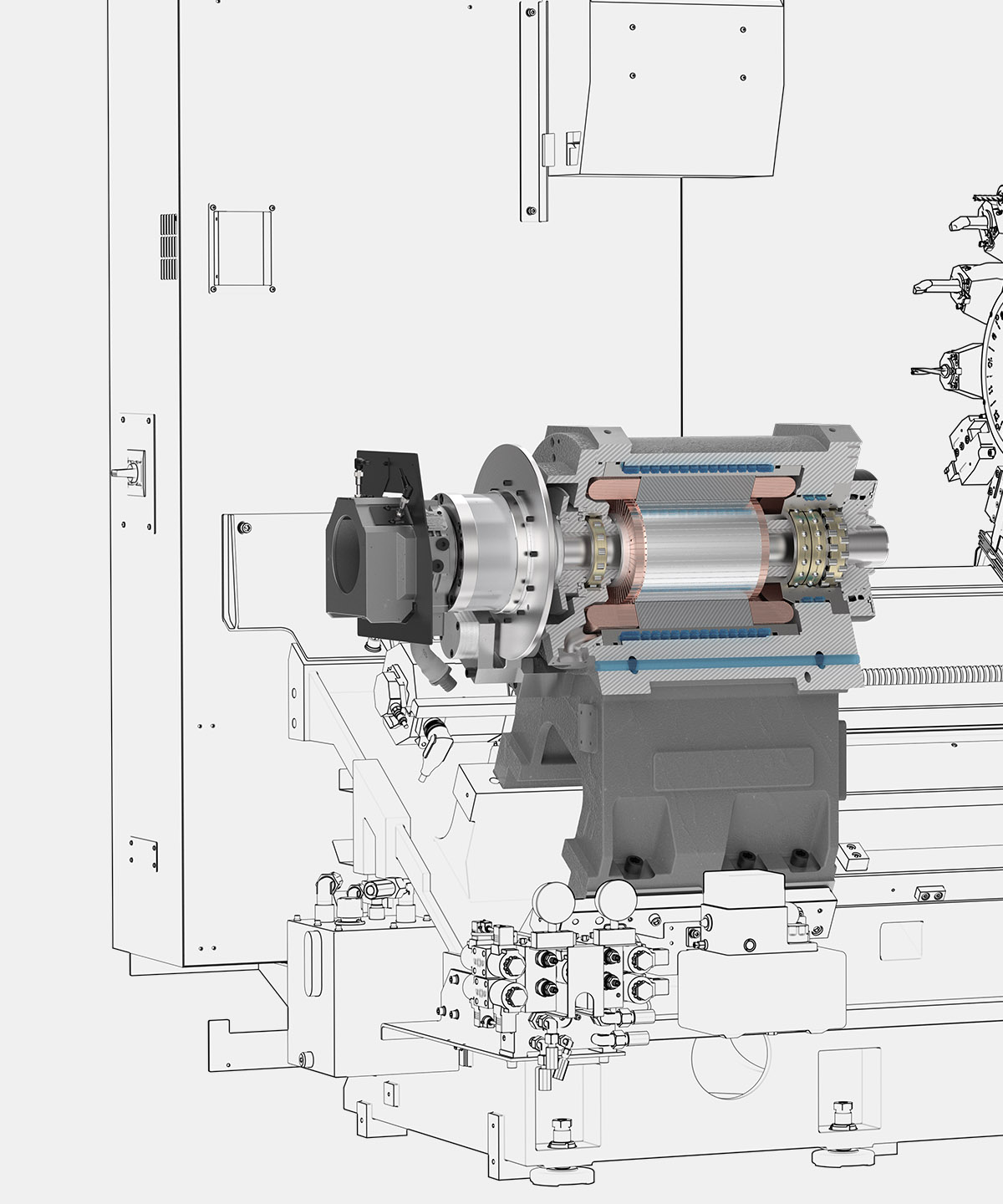

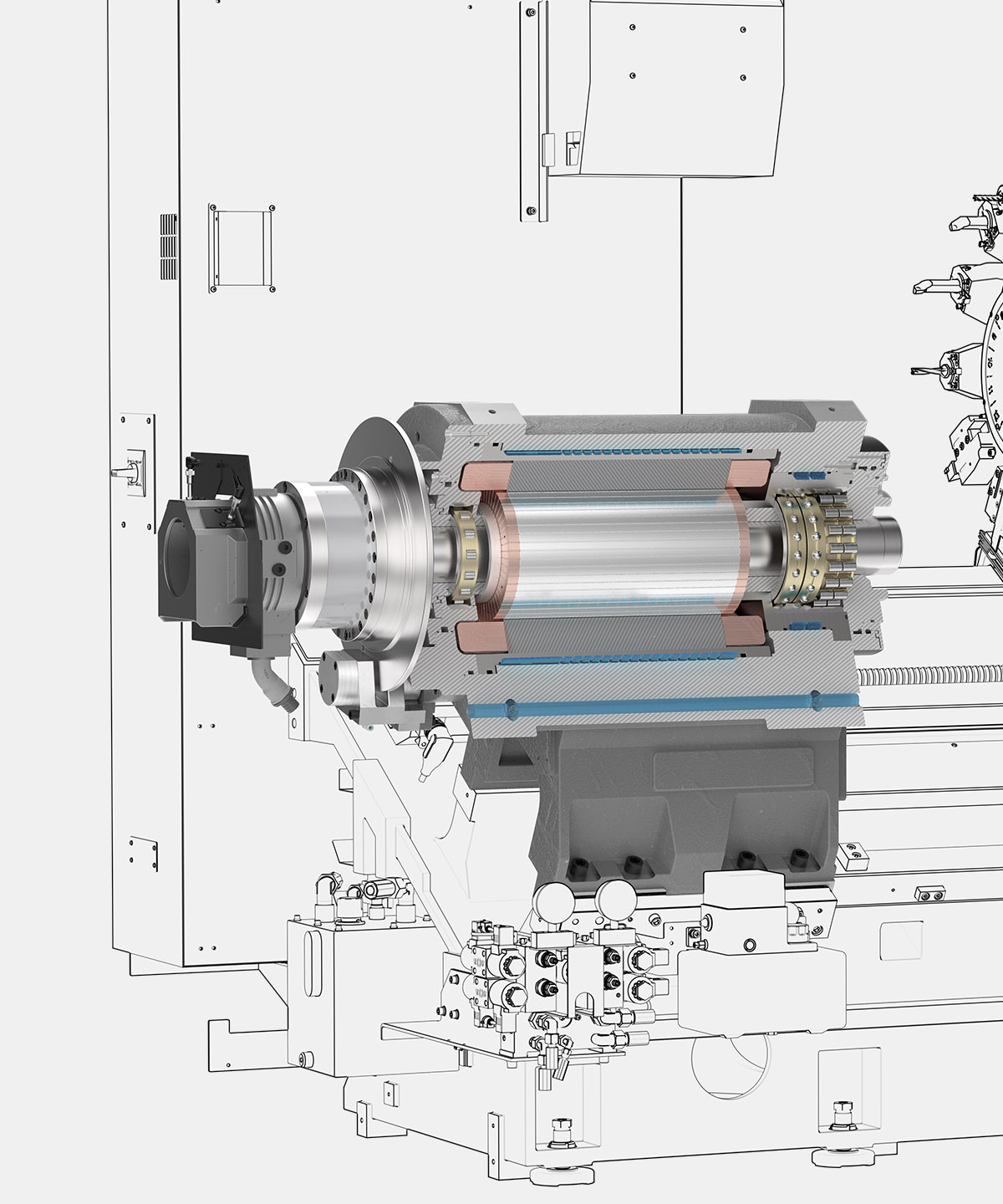

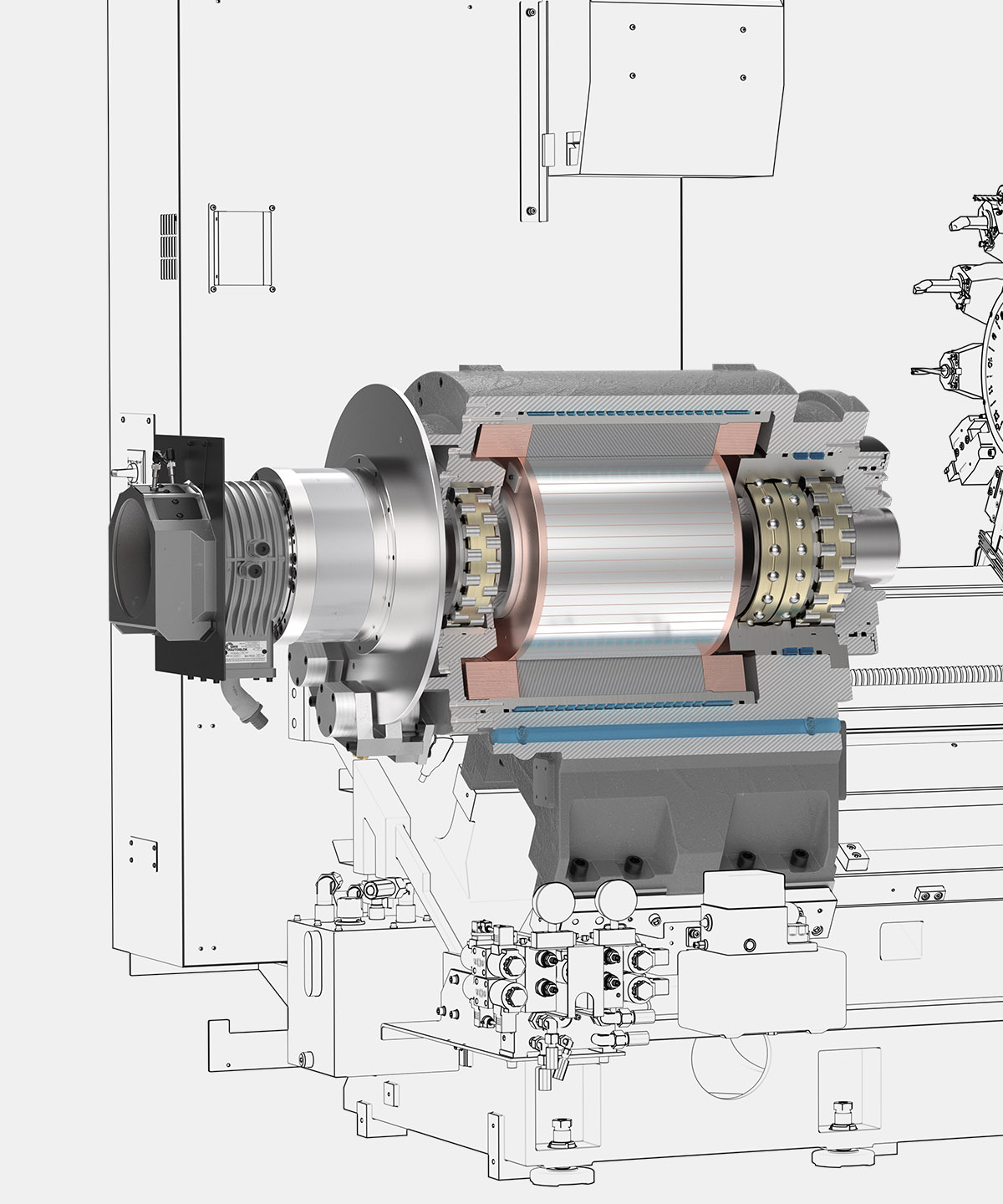

Introducing our high precision and reliability inclined bed CNC lathe. This product line allows for multiple configuration options with different tailstocks, sub-spindles, steadies, etc. In addition, the machining times are reduced thanks to the integrated headstocks.

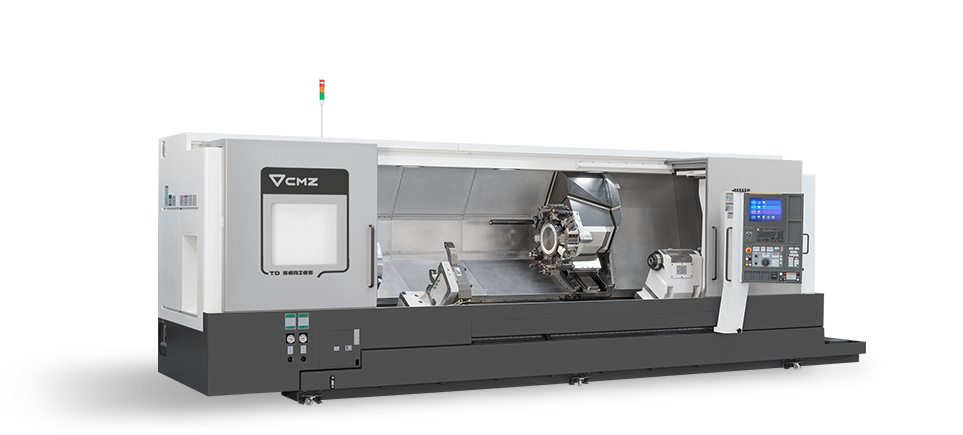

TD SERIES

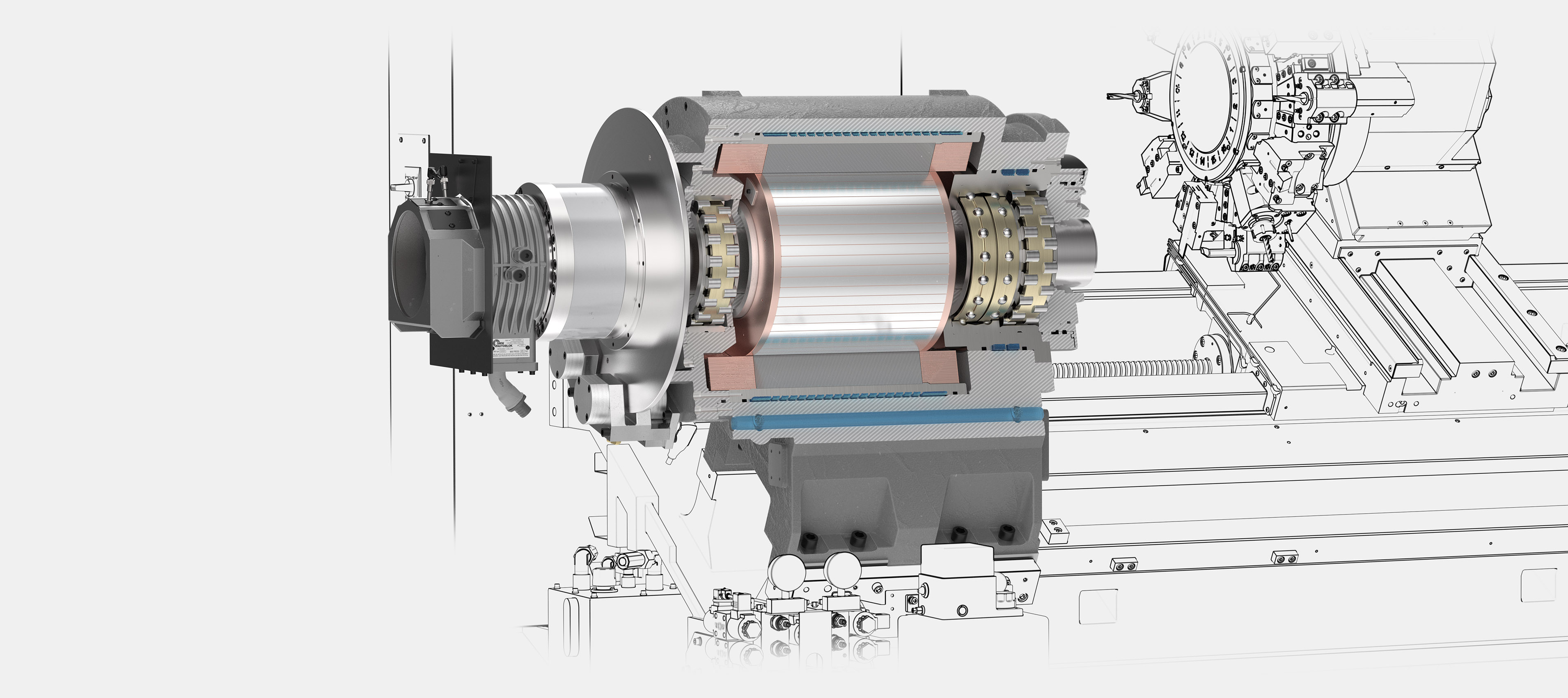

Z2200 – Z3200 | LARGE SIZES

Large does NOT mean slow: that is the phrase that sums up our large-scale lathes. You will be able to machine large workpieces in our robust and powerful machines, thanks to their beds measuring 2 and 3 metres between the chuck and tailstock.

TTS SERIES

MACHINING FOR PRECISION MACHINING FROM BAR

The smallest lathe in CMZ’s product range, forms part of the range of multi-turret machines for machining from bar. The fact that it significantly reduces cycle times, and is designed for high production, makes this CNC lathe the favourite option for companies specialising in machining complex parts from bar.

TTL SERIES

MULTI-TURRET MACHINES FOR HIGH PRODUCTION

Our beltless CNC lathe with 8 integrated motors lets you operate 3 tools at a time. What’s more, with this CNC lathe that’s specially designed for machining complex parts from bar . and high production, you are able to machine between the chuck and tailstock, while the piece is finalised in the sub-spindle.

AUTOMATION

GANTRY ROBOT LOADERS

Automate short and long batch runs with our bespoke automation solutions. Reduce dead time when loading and unloading, thanks to our range of gantry robot loaders, thereby increasing the yield of your CNC lathe. There is a type of gantry robot loader for every production process, and if there isn’t one, we can customise it.

DOWNLOAD OUR CATALOGUE TO SEE OUR FULL PRODUCT RANGE IN DETAIL

CNC LATHES FOR ALL TYPES OF APPLICATIONS

CMZ’s lathes adapt to any type of sector, regardless of the levels of production, geometries and materials. We can analyse your production needs and design the best solution for you.

SEE THE TECHNICAL SPECIFICATIONS OF OUR CNC LATHES

OUR CUSTOMERS GIVE THEIR VIEWS

Over 4,500 customers #turningtheworld with us

VÁLVULAS TORRE

The best thing about the CMZ lathes I have, is that after more than 20 years, they are still reliable and robust machines.

Daniel Vacas

HI-SPEC PRECISION ENGINEERING

I have the pleasure of owning 4 CMZ lathes, two TA’s, one TX and one TD. Each machine is a solid workhorse producing accurate parts from first thing in the morning until last thing at night. The quality of these machines is easily taken for granted but the power and accuracy is second to none. I have no regrets in investing in CMZ and would have no issues in looking to CMZ to forfil my next turning requirement.

Darren Grainger

BERETTA

The reliability and robustness of this design are the real cornerstones of this machine, as well as their ease of use and programming.

Niccolò Vizzini

RK KUTTING GMBH

CMZ is a family business. Great mechanical engineering that isn’t easy to find. Exceptional machines that make our daily life easier.

Thorsten Gaube

GERANT SARL FURMECA

Rigidity, reliability and precision for my 4 CMZs. Quality and responsiveness of the people involved in maintenance or repairs, both from the CMZ France team and its partner "Perreau Machines".

Franck Parbaud

COOLEN ENGINEERING

Our explanation of what we like best about our CMZ. First of all, the stabiliy of the machine. The ease of use the machine. The 12.000 rpm on the turret! And the best of all, it's not a DMG, Mazak, Okuma or a Doosan. No, it's a CMZ. Best build of all! :-)

Huib Coolen

FIND THE LATHE THAT’S BEST SUITED TO YOUR REQUIREMENTS

WE ARE CMZ

LEADING EUROPEAN CNC LATHE MANUFACTURER

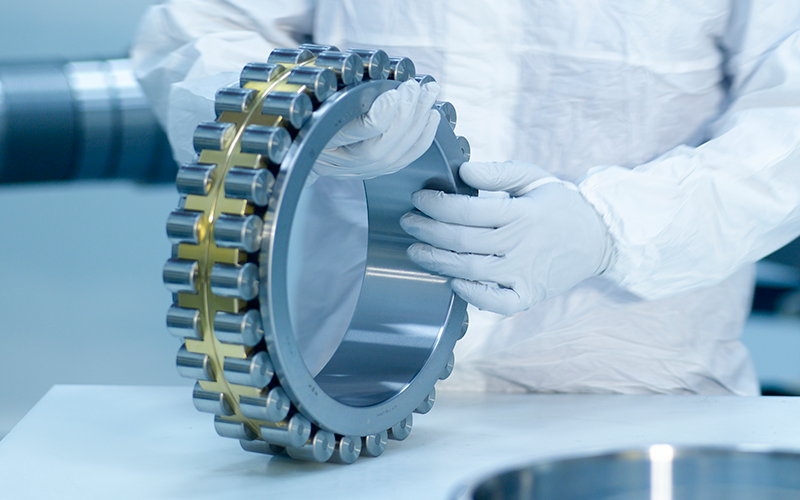

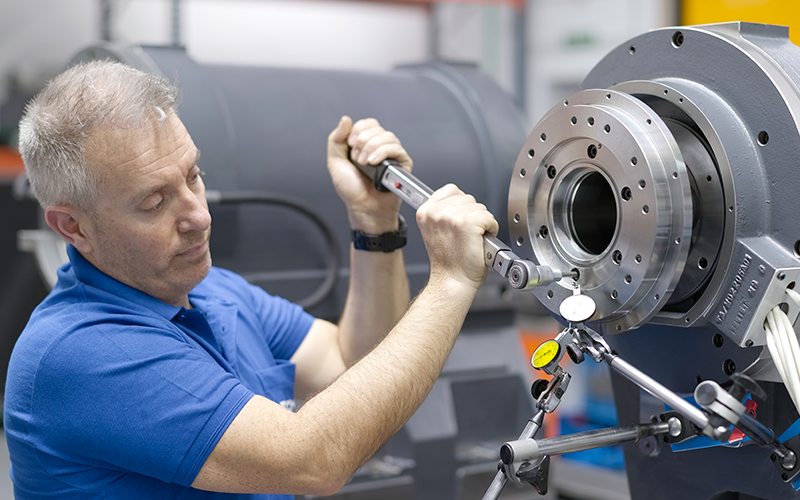

CMZ is a family business with an international dimension and more than 75 years of history. We manufacture the vast majority of the parts that make up our lathes in the more than 32.000 m2 of floor space that compose our manufacturing plants.

Our team of more than 450 people, 4 European subsidiaries and the 11 international distributors, make possible for us to deliver an average of 3 powerful, precise and reliable lathes per day, manufactured with great care at every stage of productive process. Machines with a life cycle of more than 20 years at the service of more than 4.500 customers who are already #turningtheworld with us.

OUR MANUFACTURING PLANTS

THE POWER OF A MANUFACTURER

CENTRAL SERVICES

Zaldibar - Spain

MACHINING PLANT

10.000m2 | Mallabia - Spain

SHEET METAL PLANT

15.000m2 | Cádiz - Spain

ASSEMBLY PLANT

10.000 m2 | Mallabia - Spain

MACHINING PLANT

4.900m2 | Elorrio - Spain

MACHINING PLANT

970m2 | Elorrio - Spain

ASSEMBLY PLANT FOR ELECTRICAL CABINETS

1.250m2 | Zaldibar - Spain

DISTRIBUTION NETWORK ACROSS THE WHOLE OF EUROPE

ROBUST, POWERFUL AND PRECISE CNC LATHES

We have what you need

Here at CMZ, we have been manufacturers of machine tools for over 75 years, and we like what we do. Whatever your production needs, our range of CNC lathes can adapt thanks to their versatility and precision. All of our team are always close to you: thanks to our subsidiaries spread out across the whole of Europe, we are able to offer a personalised after-sales service that is adapted to any circumstance. We manufacture the CNC lathe you need, with the best features on the market. We want you to discover our wide range of CNC lathes, join us!

TA SERIES

We present to you our bestselling CNC lathe. If you are looking for a high performance, powerful and reliable CNC lathe, the TA Series offers 3 different bed lengths (Z400, Z640 and Z1100), with multiple configuration options. CNC lathes with solid prismatic/box guideway beds which also include a turret with an integrated 12,000rpm driven tool motor, as well as integrated headstocks cooled with oil. You are also able to automate long and short batch runs with our gantry solutions.

TD SERIES

Z800 – Z1350

Discover a wide range of possibilities in your machining with our larger CNC lathe. You will be able to reduce machining times thanks to the integrated headstocks, and since they don’t have belts or pulleys, they generate less noise and produce a better surface finish. A CNC lathe that incorporates an oil-cooled turret with up to 16 positions, and an indexing time of 30º in 200 ms.

TD SERIES

Z2200 – Z3200

Large does NOT mean slow: that is the phrase that best sums up our range of large-scale CNC lathes. If your objective is to machine large shafts, without sacrificing accuracy and rigidity, you will find the large-scale lathe you are looking for in this range. You will be able to machine almost without limits on our CNC lathe, thanks to its beds measuring 2 and 3 metres between the chuck and tailstock.

DRILL HOLES LONGER THAN 42 TIMES THE DIAMETER IN A LATHE

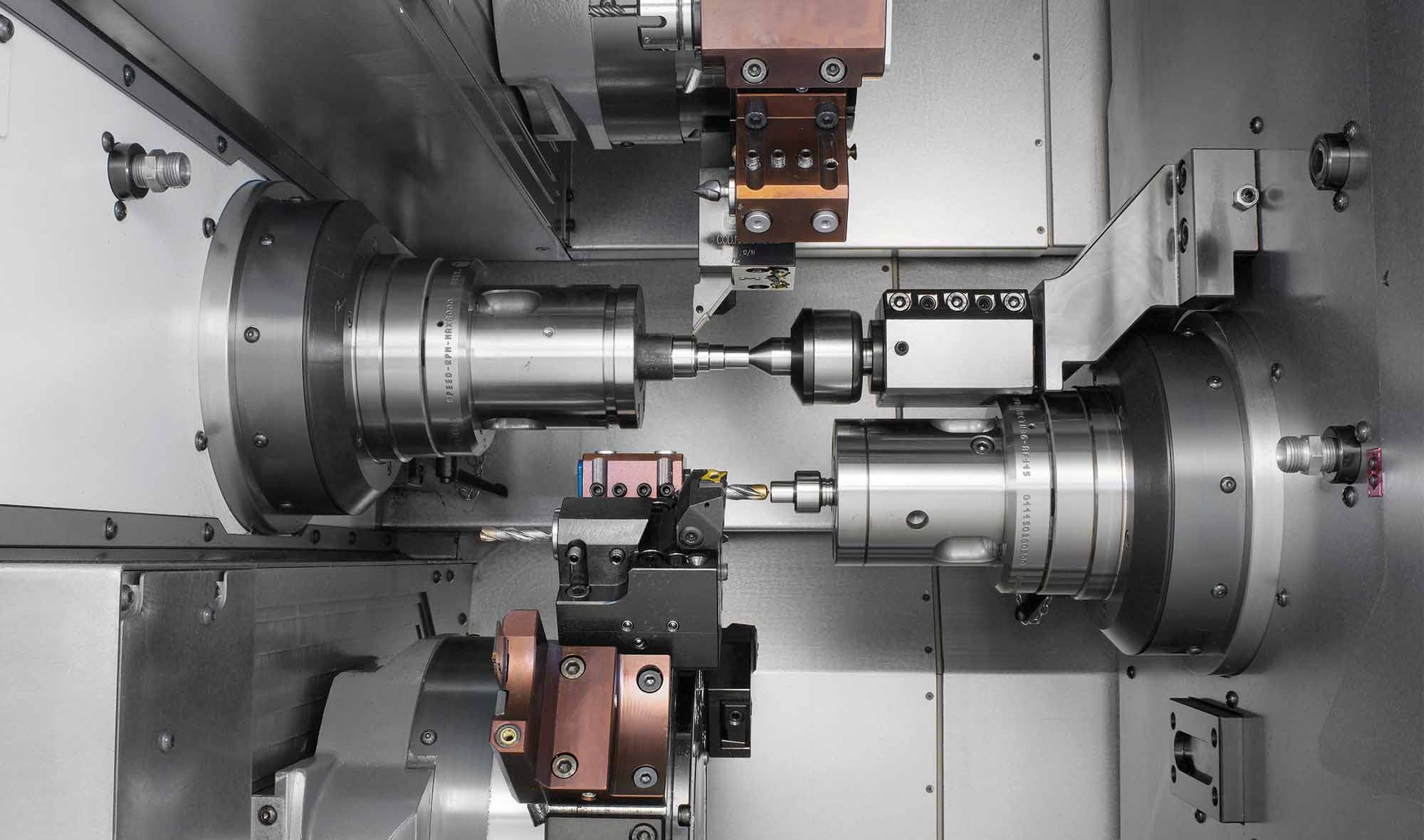

TTS SERIES

If you specialise in longer production runs, where every second counts, and you want to significantly reduce your cycle times, we present you with our range of CNC lathes specially designed for machining complex parts from bar . This is the smallest lathe in our range of multi-turret machines, ideal for machining complex parts due to its speed, accuracy and reliability. It reduces the acceleration time by 50%, reaching 5,000rpm in 1.75 seconds, thanks to its high power motors.

FEATURES

DISCOVER EXCLUSIVE FEATURES IN THIS FIXED HEAD LATHE THANKS TO THE MOVEMENTS IN THE X3 AND Z3 AXES

Incorporates a tailstock (optional)

One of the options of this small fixed head lathe is the tailstock attached to the body of the sub-spindle. The tailstock can be mounted above or below the sub-spindle.

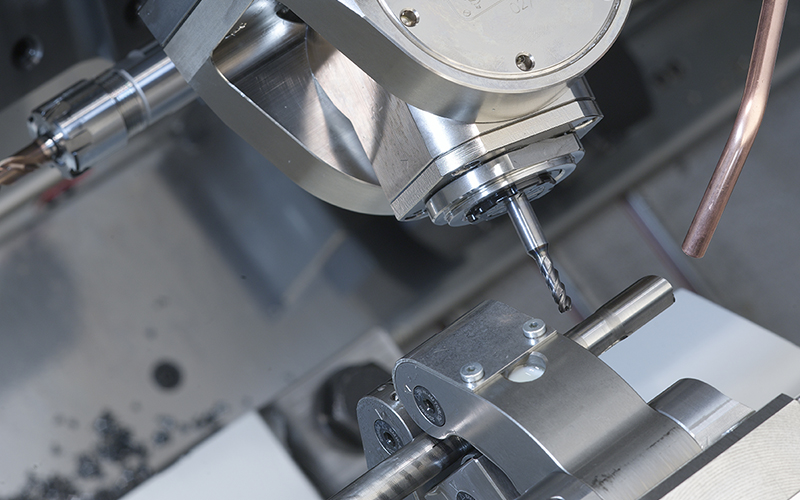

Simultaneous operation with 3 tools

This fixed head CNC lathe has two turrets, but the CNC has 3 channels to run 3 programs at once, each with its own offset. The sub-spindle (axes X3 and Z3) can operate in channel three of the CNC jointly with both the upper turret and the lower one.

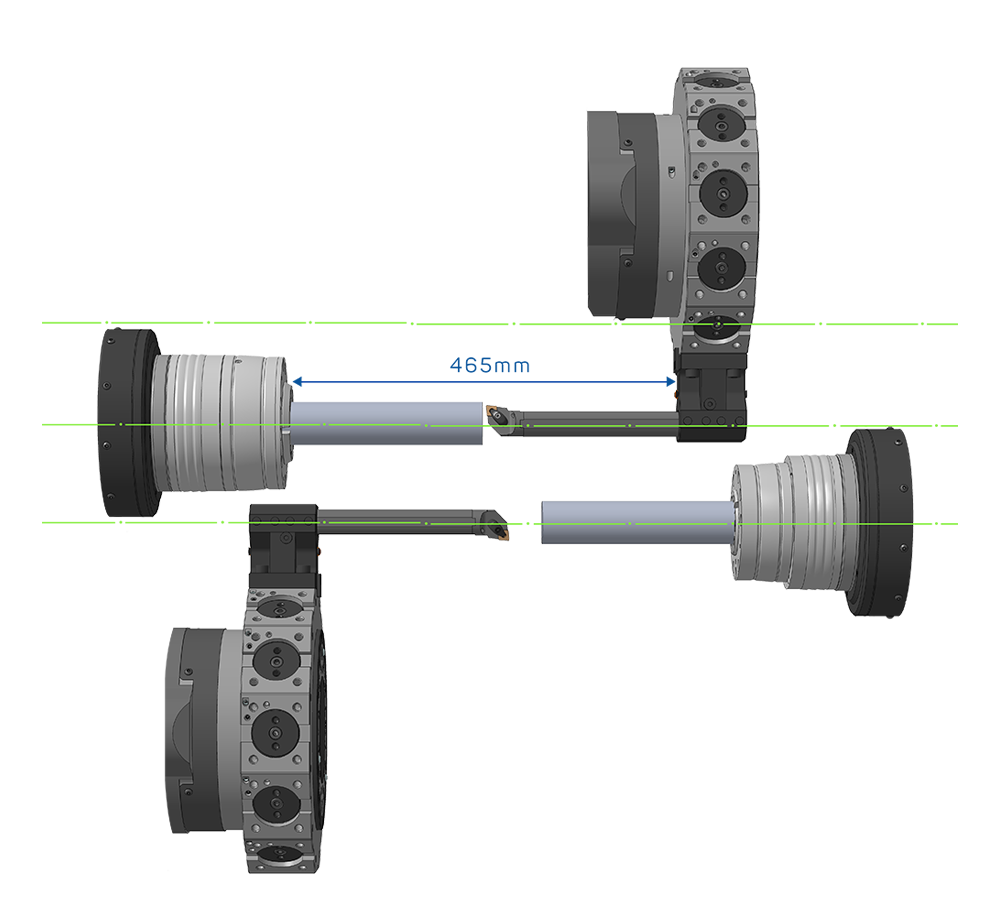

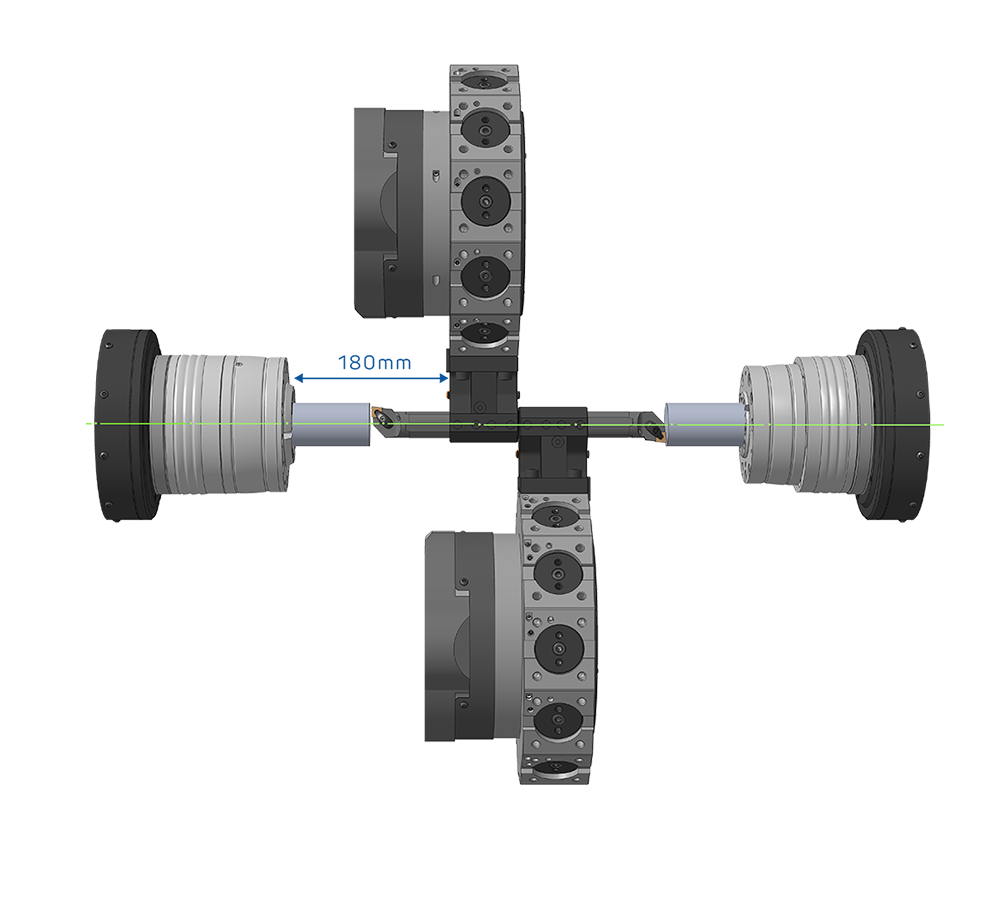

MACHINE LONGER PARTS

THE VERTICAL MOVEMENT OF THE SUB-SPINDLE REDUCES INTERFERENCES

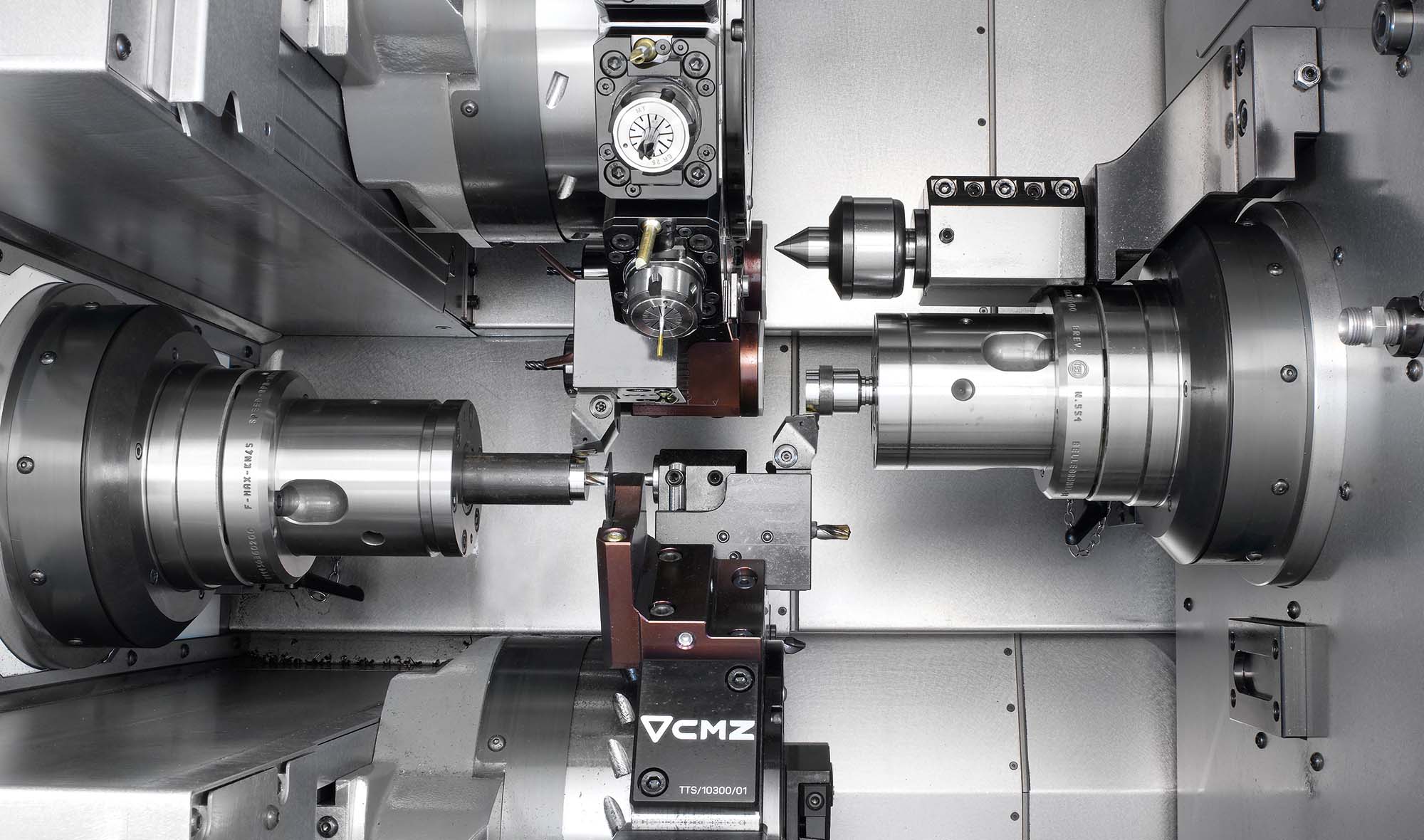

TTL SERIES

A star is born. Within our range of multi-turret CNC lathes designed for longer production runs machining complex parts from bar, we present the TTL series, a CNC lathe designed for longer production runs. It is our CNC lathe without belts, and with 8 integrated motors. Thanks to its synchronous headstocks, you will halve the acceleration time, to as low as 4,000rpm in 1.73 seconds.

Features

THE MOVEMENTS ON THE X3 AND Z3 AXES ALLOW FOR EXCLUSIVE FUNCTIONS:

- Incorporate counterpoint.

- Operate with 3 tools simultaneously.

- Machine longer parts thanks to the reduction in interferences.

Work simultaneously with tailstock and sub-spindle

Optionally, this CNC lathe can incorporate a tailstock attached to the body of the sub-spindle. With it, you can machine between the chuck and tailstock while finishing the part in the sub-spindle, as shown in the photo.

Simultaneous operation with 3 tools

This fixed head CNC lathe has two turrets, but the CNC has 3 channels to run 3 programs at once, each with its own offset. The sub-spindle (axes X3 and Z3) can operate in channel three of the CNC jointly with both the upper turret and the lower one.

THE VERTICAL MOVEMENT OF THE SUB-SPINDLE REDUCES INTERFERENCES AND ALLOWS WORK TO BE DONE ON LONGER WORKPIECES

TTL SERIES

OTHER MACHINES

AUTOMATION

GANTRY LOADER

Automate your short and long runs with our bespoke automation solutions. If your aim is to reduce dead time when loading and unloading, in order to be able to attend to the rest of your workshop, our range of gantry robots can be your best ally. A simpler solution than anthropomorphic robots: more economical, quicker, and with simple conversational programming software. There is a gantry loader for every production process, and if you don’t think there is... we can customise it!