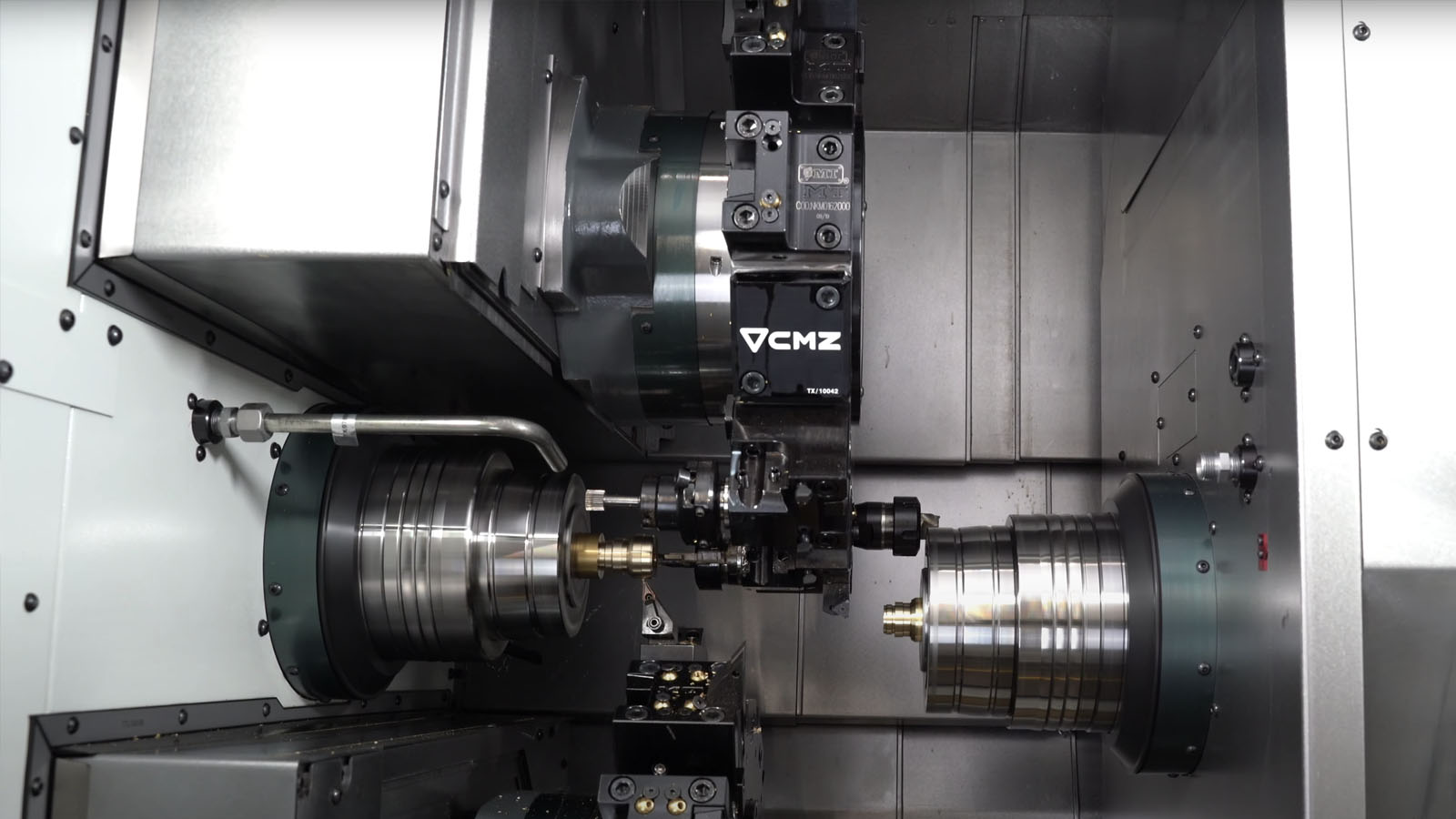

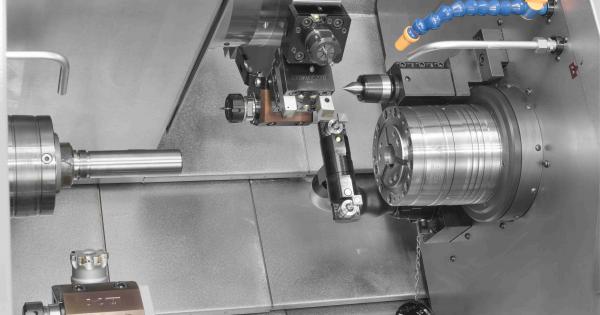

This powerful 66mm bar capacity twin turret twin spindle CNC lathe can cut with 3 or even 4 tools simultaneously making the TTL a great machine for producing higher volumes of complex parts.

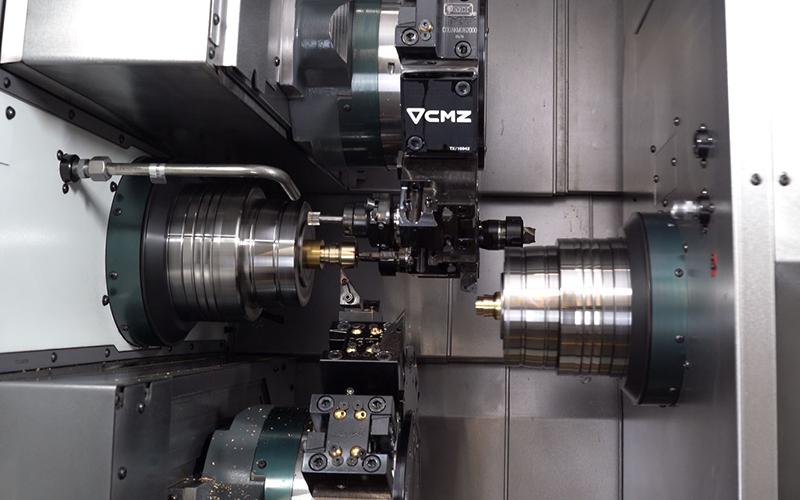

Superimposed machining is made possible by a combination of sub-spindle axis movement in X and Z and 3 programming channels permitting the machine to cut with 3 or even 4 tools at the same time. This functionality is not limited to simple trajectories, thread cutting is possible too.

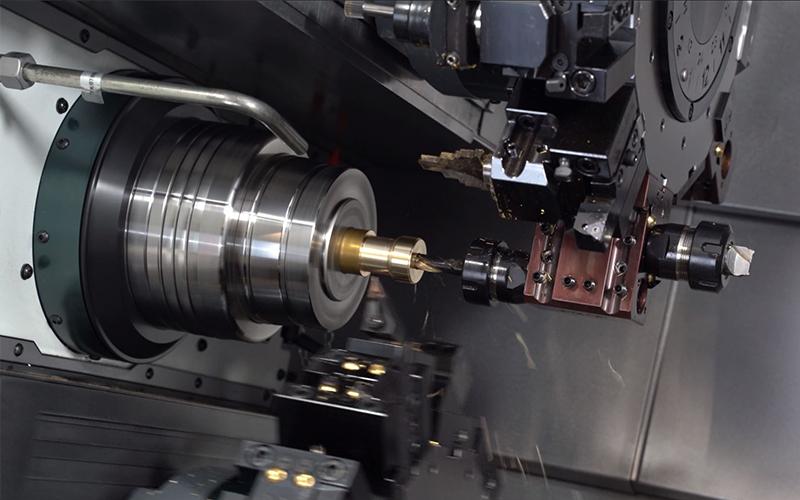

In this video, we show the machining of a brass component using form tools to reduce cycle times. It is observed how the thread cutting is done with superimpose as two other tools are machining at the same time.

Programming superimposed machining should not be a challenge for the operators, each trajectory is programmed separately and using an M code two channels are superimposed.

Superimposed machining is a very powerful feature on the TTL and opens up a broad range of options for machining processes.

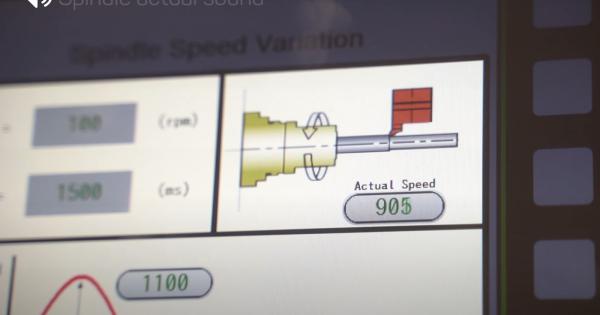

Chatter must be avoided at all costs. Chatter not only produces a poor surface finish on diameters but also seriously limits tool life. Long slender shafts, extended boring bars, thin walls and so on, can present real challenges. Spindle Speed Variation function allows the spindle speed to fluctuate…

Material is a considerable percentage in component cost. In order to avoid large material waste on the cut off, the blades are usually very thin and long, which often lead to vibrations and bad surface finish. The only solution is to reduce the tool overhang to minimise the effect; however, the…

When the geometry of the part allows it, it is even possible to cut with four tools at the same time performing a double balance cutting process. One of the turrets and the subspindle (TOOL 1+TOOL 2) will be programmed with superimpose function and the other turret will be programmed as a single trajectory…

CMZ presents their new CNC lathe series TTL. This a new generation of lathe that can be included in the multiturret range together with the TX series. Its rapid speed of 30m/min, milling capacity up to 12,000rpm and machine bed inclination of 60° makes it ideal for bar work. The lathe consists of…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.