Material is a considerable percentage in component cost. In order to avoid large material waste on the cut off, the blades are usually very thin and long, which often lead to vibrations and bad surface finish. The only solution is to reduce the tool overhang to minimise the effect; however, the shortening limits the capacity to part off larger diameters.

To overcome this challenge, Sandvik Coromant has developed a new concept where they use an element that traditionally has been used for milling, the machine Y axis for part off. Just by changing the cutting direction, they have managed to increase resistance to flection, which allows longer overhangs and faster cutting conditions as the force is directed towards the tool axis. Surface finish is also improved.

In CMZ we have identified this application and considered it quite interesting to be used in our machines; that is why we have prepared the machines for this purpose. This document will give you all the information you require to setup both tool and program in all our CNC lathe series, provided they are configured with Y axis.

Discover all the programming tips with this free downloadable

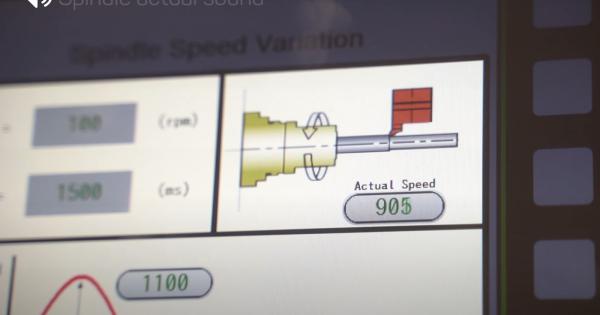

Chatter must be avoided at all costs. Chatter not only produces a poor surface finish on diameters but also seriously limits tool life. Long slender shafts, extended boring bars, thin walls and so on, can present real challenges. Spindle Speed Variation function allows the spindle speed to fluctuate…

A solution to automate the process of machining shafts in your CNC lathe. Our GL20II gantry loader system combined with the WS700 workstocker for shafts allows you to leave you machines running unmanned. You can have several parts in each line up to 700mm. Controlling the robot is very easy and you…

One of the most critical aspects in many machining processes is chip formation. Long and entangled chips are formed mainly in turning operations due to constant cutting conditions. This issue requires changes in the process; such as modifying machining parameters or changing tools to get into a safer…

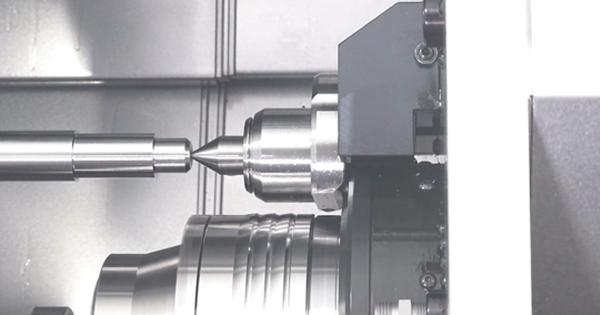

With this configuration, customers can machine parts in the main-spindle with the tailstock engaged using the upper turret, while simultaneously machining parts in the sub-spindle with the lower turret. Working with a tailstock on a TTL or TTS is a very productive option because of the ability to work…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.