OKUMA LB 2000 EX II VS. CMZ TA

TECHNICAL SPECIFICATION COMPARISON

-

LB 2000 EX II

Single turret CNC lathe - High precision CNC lathe and prismatic guides

- Bar capacity Ø62, or Ø80 mm

- Maximum turning Ø= 430 mm

- X travel = 260 mm

- Y travel = +70 /-50 mm

- Z travel = 390 or 565

- Fast feeds (m/min): X=25, Y=12.5, Z=30

- Spindle with integrated motor

- Standard spindle 160 Nm / 11 kW (20 min)

- Sub-spindle 80Nm / 11kW (20 min)

- 12-position turret

- Belt-driven turret 6,000 rpm,

- Motorised turret 31 Nm/ 5.5 kW (2 min)

- Gantry Loader not available on European or American markets

-

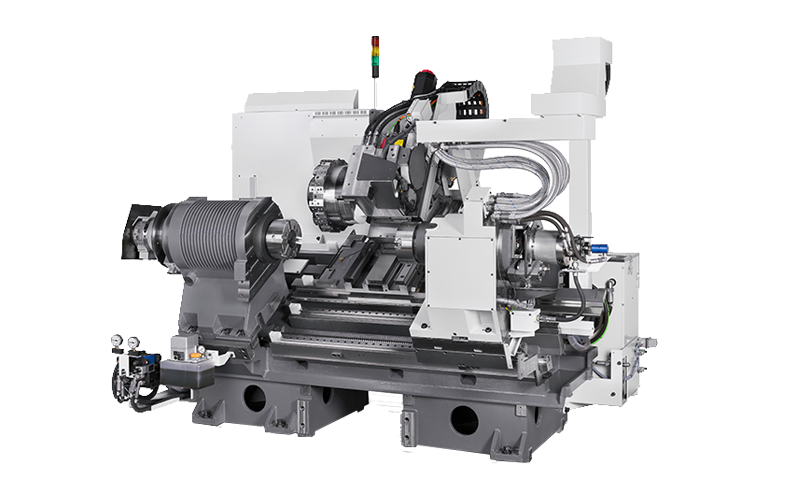

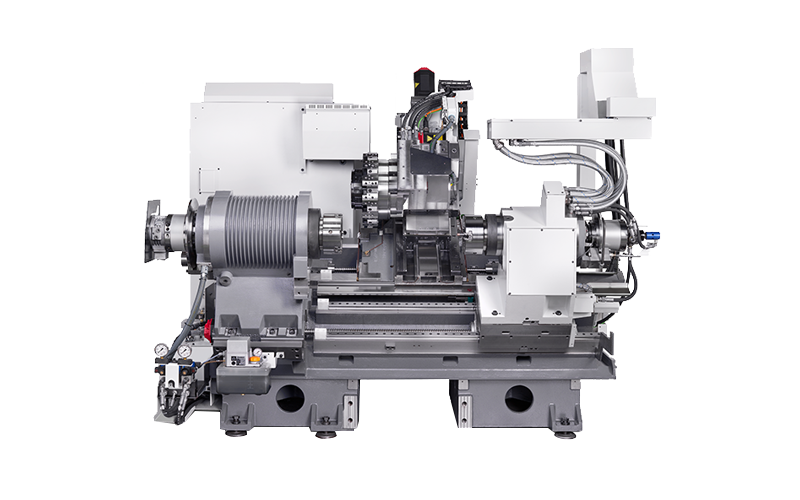

CMZ TA

Single turret CNC lathe - High precision CNC lathe and prismatic guides

- Multiple bar capacity options: Ø52, Ø66 or Ø82

- Maximum turning Ø= 450 mm

- X travel = 310 mm

- Y travel = +70 /-50 mm

- 3 sizes of bench, Z=400, 640 or 1100 mm

- Fast feeds (m/min): X=30, Y=15, Z=30

- Spindle with integrated motor

- TA-25 spindle: 900 Nm / 35 kW (max)

- Sub-spindle 292 Nm / 14 kW (max)

- 12- or 15-position turret

- Turret with integrated motor 12,000 rpm

- Motorised turret 75 Nm / 11.3 kW (max)

- 3-axis Gantry Loader max weight 20 kg

OKUMA LB 2000 EX II VS. CMZ TA

DO YOU WANT TO ACCESS THE FULL TECHNICAL DETAILS?

HIGH PERFORMANCE CNC MACHINE FOR SALE WITH PRISMATIC BED

COMPARE LB 2000 EX II WITH CMZ TA

DISCOVER THE MAIN DIFFERENCES BETWEEN THESE LATHES

The CMZ TA and the LB2000 EX II are CNC lathes in the same segment, but with significant differences in terms of features and design.

The CMZ TA has a more powerful standard spindle, reaching 1020 Nm and 42 kW maximum power, whereas the LB2000 EX II reaches 160 Nm and 22 Kw in S2 (20 min). The TA sub-spindle also has torque and power specifications as it reaches 292 Nm and 14 kW.

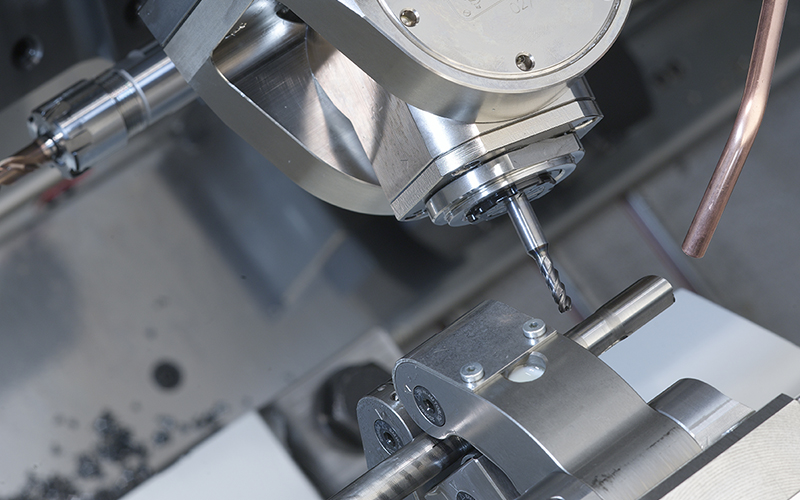

The CMZ TA turret can have 12 or 15 positions and is designed with an integrated motor which reaches 12,000 rpm continuous power. The LB2000 EXII turret has 12 positions and reaches a maximum of 6,000 rpm. In addition, the CMZ TA has a high milling capacity: 75 Nm and 11.3 kW.

As regards automation, the CMZ TA can be acquired on any market with a Gantry loader and work stocker for flanges or axles.

CMZ TA IN ACTION

GET TO KNOW IN DEPTH ALL THE FUNCTIONALITIES OF THE TA SERIES

WE ARE CMZ

LEADING EUROPEAN CNC LATHE MANUFACTURER

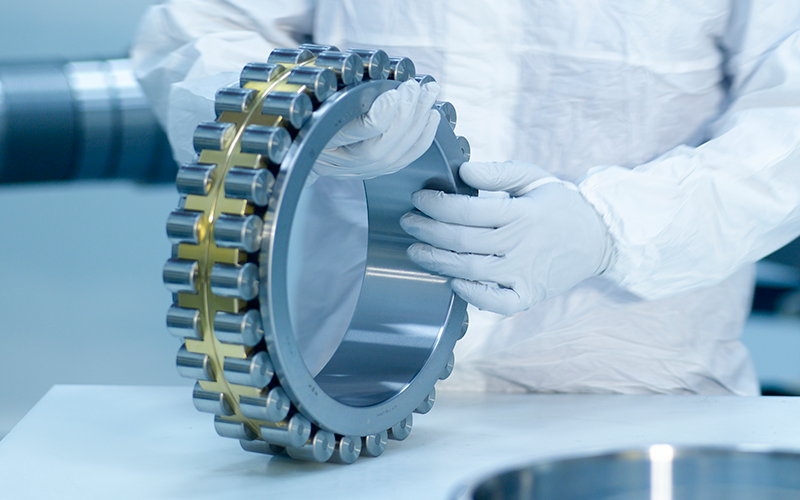

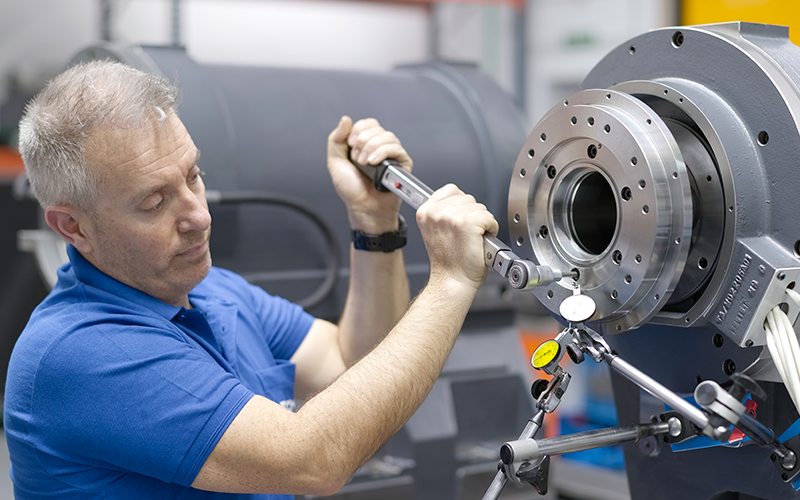

CMZ is a family business with an international dimension and more than 75 years of history. We manufacture the vast majority of the parts that make up our lathes in the more than 40.000 m2 of floor space that compose our manufacturing plants.

Our team of more than 500 people, 5 European subsidiaries and the 11 international distributors, make possible for us to deliver an average of 3 powerful, precise and reliable lathes per day, manufactured with great care at every stage of productive process. Machines with a life cycle of more than 20 years at the service of more than 4.500 customers who are already #turningtheworld with us.

OUR MANUFACTURING PLANTS

THE POWER OF A MANUFACTURER

CENTRAL SERVICES

Zaldibar - Spain

MACHINING PLANT

10.000m2 | Mallabia - Spain

SHEET METAL PLANT

15.000m2 | Cádiz - Spain

ASSEMBLY PLANT

10.000 m2 | Mallabia - Spain

MACHINING PLANT

4.900m2 | Elorrio - Spain

MACHINING PLANT

970m2 | Elorrio - Spain

ASSEMBLY PLANT FOR ELECTRICAL CABINETS

1.250m2 | Zaldibar - Spain