NAKAMURA TOME WY 100 V VS. CMZ TTS

TECHNICAL SPECIFICATION COMPARISON

-

WY 100 V

CNC LATHE WITH TWO TURRETS, BOTH WITH Y AXIS. - Ø42, Ø51, Ø65 BAR CAPACITY

- 2 CHANNELS Not possible to work with 3 tools simultaneously

- Spindle and sub-spindle with belts

- Belts between X axis motors and screws

- Mitsubishi Control

- No tailstock option possible

- 10,000 rpm, 7.5 kW motorised turret

- X travel: 150 mm

- Y travel: ±42 mm

- Z travel: 588 mm

- Parts catcher: Maximum length of part 100 mm

- Floor space: 3,849 mm x 2,245 mm

-

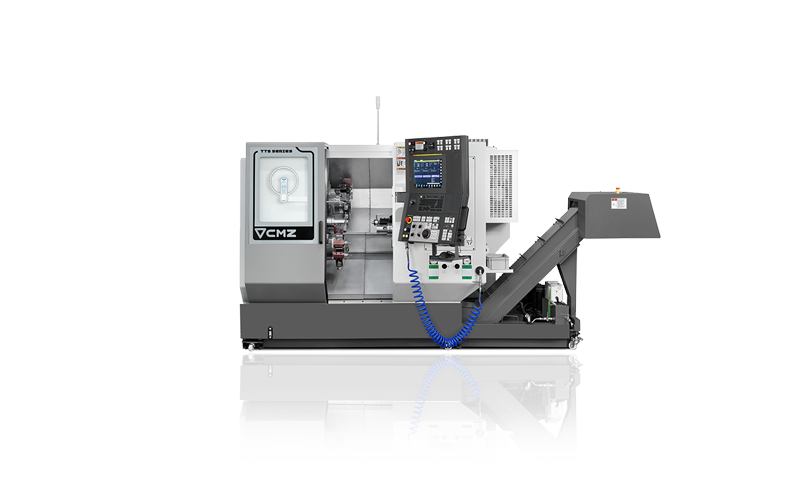

CMZ TTS

ALLOWS SIMPLER CONFIGURATIONS (EVEN WITHOUT DRIVEN TOOLS). - Ø38, Ø46, Ø52 and Ø66 BAR CAPACITY

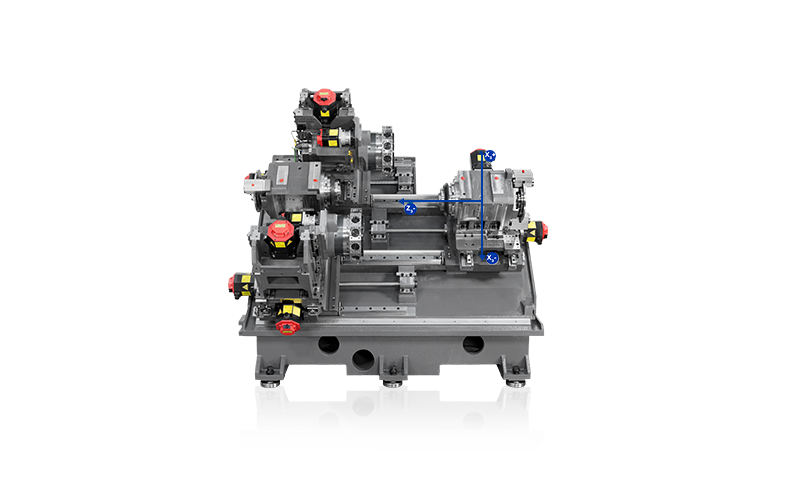

- 3 CHANNELS Possible to work with 3 tools simultaneously

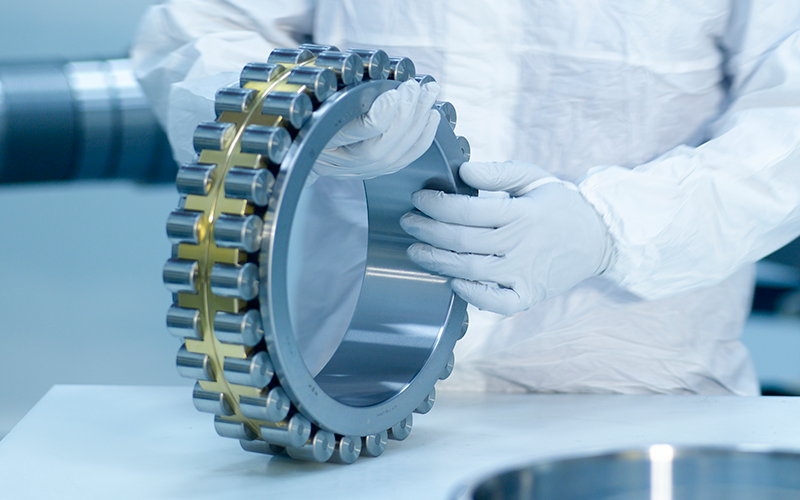

- Spindles with integrated motor (no belts), oil cooled

- X and Y axis screws activated directly without belts

- Fanuc Control

- Tailstock (optional)

- 12,000 rpm, 26.8 Nm, 13.2 kW motorised turret

- X travel: 100 mm

- Y travel: ±45 mm

- Z travel: 368 mm

- Parts catcher: Maximum length of part 160 mm

- Floor space: 2,910 mm x 1,650 mm

NAKAMURA WY 100 V VS. CMZ TTS

DO YOU WANT TO ACCESS THE FULL TECHNICAL DETAILS?

MULTI-TURRET LATHE FOR BAR TURNING

COMPARE NAKAMURA WY 100 V WITH CMZ TTS

DISCOVER THE MAIN DIFFERENCES BETWEEN THESE BAR TURNING LATHES

The Nakamura WY 100 V and CMZ TTS are lathes designed for the same type of part, they can be described as competitors. Nevertheless, analysis of their features shows there are technical differences.

The CMZ TTS has integrated motors, all oil-cooled to provide movement to the spindles, X and Y motors, and driven tool. The Nakamura Tome WY-100 V has belts on both spindles and on X movements on the lower turret.

The TTS has an X3 axis unlike the Nakamura Tome WY-100 V .

This feature permits:

- The simultaneous use of 3 tools, each tool governed by a different program executing on a different channel.

- The inclusion of a tailstock mounted on the sub-spindle.

- The X3 movement in the sub-spindle significantly reduces interferences between the turrets because it moves the lower turret, thereby allowing the use of mandrels and longer drill bits.

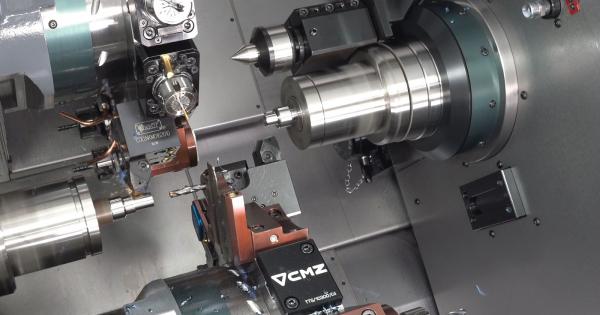

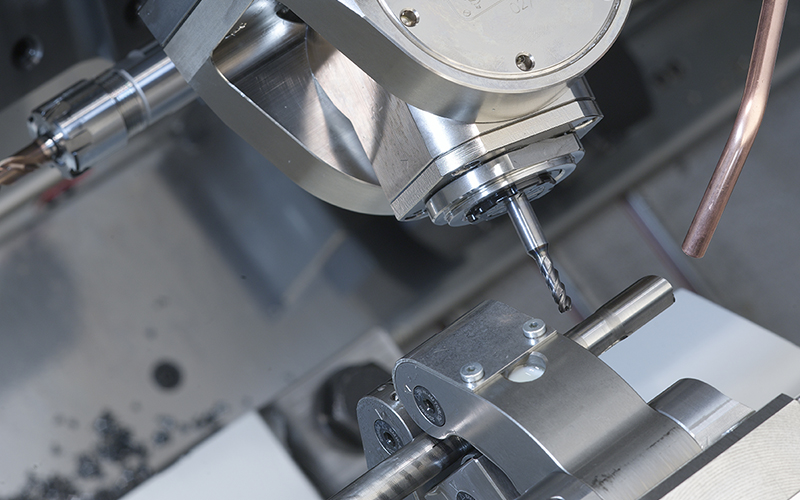

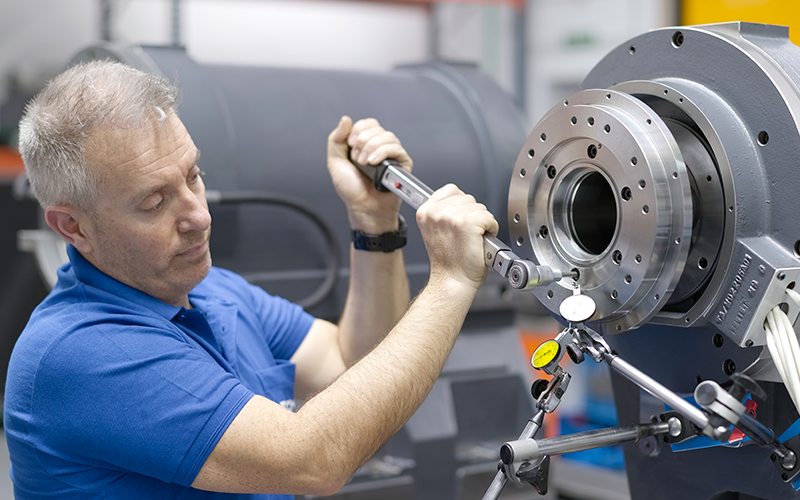

CMZ TTS IN ACTION

GET TO KNOW IN DEPTH ALL THE FUNCTIONALITIES OF THE TTS SERIES

WE ARE CMZ

LEADING EUROPEAN CNC LATHE MANUFACTURER

CMZ is a family business with an international dimension and more than 75 years of history. We manufacture the vast majority of the parts that make up our lathes in the more than 40.000 m2 of floor space that compose our manufacturing plants.

Our team of more than 550 people, 5 European subsidiaries and the 11 international distributors, make possible for us to deliver an average of 3 powerful, precise and reliable lathes per day, manufactured with great care at every stage of productive process. Machines with a life cycle of more than 20 years at the service of more than 4.500 customers who are already #turningtheworld with us.

OUR MANUFACTURING PLANTS

THE POWER OF A MANUFACTURER

CENTRAL SERVICES

Zaldibar - Spain

MACHINING PLANT

10.000m2 | Mallabia - Spain

SHEET METAL PLANT

15.000m2 | Cádiz - Spain

ASSEMBLY PLANT

10.000 m2 | Mallabia - Spain

MACHINING PLANT

4.900m2 | Elorrio - Spain

MACHINING PLANT

970m2 | Elorrio - Spain

ASSEMBLY PLANT FOR ELECTRICAL CABINETS

1.250m2 | Zaldibar - Spain