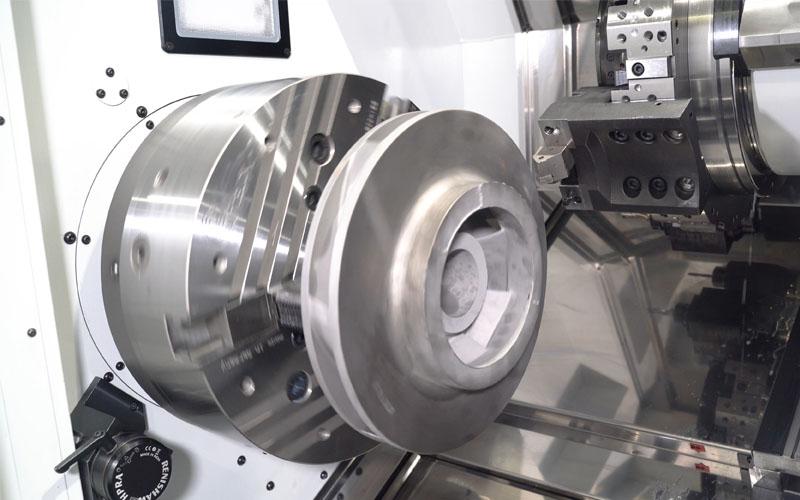

Machining stainless steel, duplex or super duplex requires that the machine tool used is robust, stable and with an adequate power due to the mechanical characteristics of these materials. The lathe TD series adapts perfectly to these needs, which makes it ideal to machine materials like the aforementioned stainless steel, duplex or super duplex.

While the diameter of the parts gets bigger, the power and torque diagrams become more important because the spindle speed is minimal. Thanks to the great torque of the TD45 and TD55 spindles (high precision lathes from TD Series), CMZ machines are capable to machine super duplex parts in large diameters with a spindle speed as minimal as 20rpm using large depths of cuts.

The large depths of cuts allow to cut through the hardened pass created by previous passes when machining super duplex without compromising the stability of the machine due to the large torque the machine has at low speeds. The robustness and stability of the machine also avoid the vibrations that could compromise the quality of the machining. These great advantages combined with the CMZ developed high pressure coolant systems and the coolant chiller makes possible to machine large parts with tight tolerances.

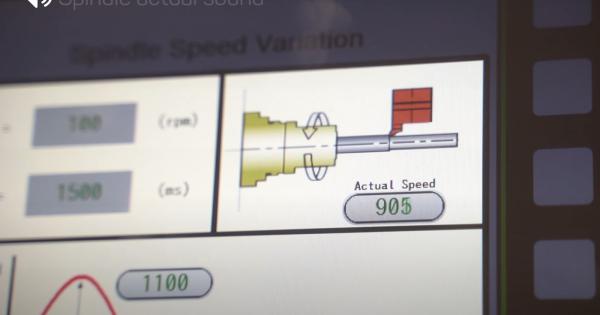

Chatter must be avoided at all costs. Chatter not only produces a poor surface finish on diameters but also seriously limits tool life. Long slender shafts, extended boring bars, thin walls and so on, can present real challenges. Spindle Speed Variation function allows the spindle speed to fluctuate…

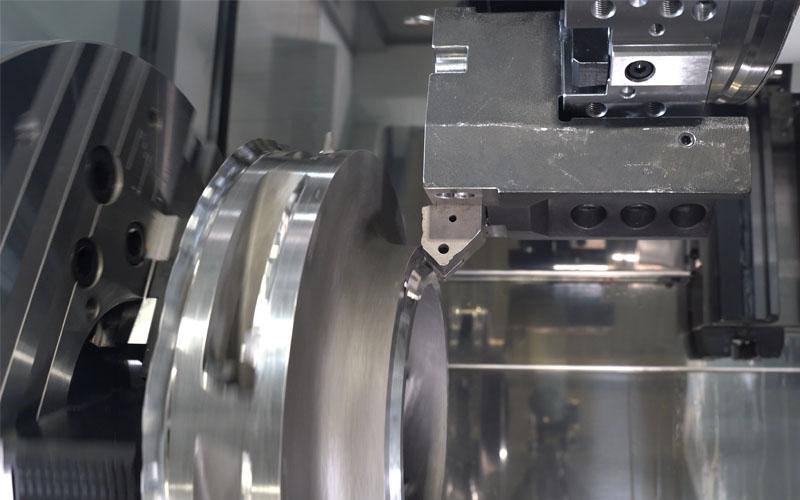

Material is a considerable percentage in component cost. In order to avoid large material waste on the cut off, the blades are usually very thin and long, which often lead to vibrations and bad surface finish. The only solution is to reduce the tool overhang to minimise the effect; however, the…

A solution to automate the process of machining shafts in your CNC lathe. Our GL20II gantry loader system combined with the WS700 workstocker for shafts allows you to leave you machines running unmanned. You can have several parts in each line up to 700mm. Controlling the robot is very easy and you…

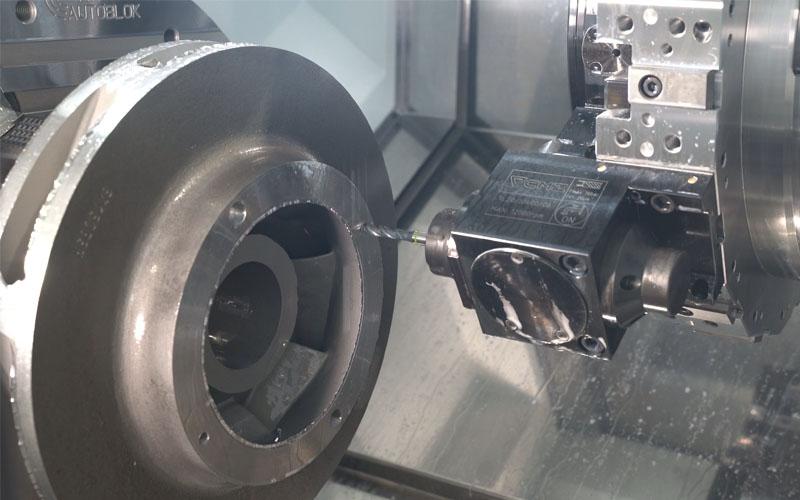

One of the most critical aspects in many machining processes is chip formation. Long and entangled chips are formed mainly in turning operations due to constant cutting conditions. This issue requires changes in the process; such as modifying machining parameters or changing tools to get into a safer…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.