At CMZ we have been manufacturers in the machine tools market for 80 years. 80 years in which we have had to adapt and reinvent ourselves on numerous occasions. And even in these uncertain times, we have made a strong commitment to our philosophy of in-house production. And now we are about to open the doors onto 2025, it's time to look back and raise a toast.

This year was full of projects directed towards growth and by extension to new investments. As part of the plan to increase production capacity to 1,000 machines a year, in July we acquired a 22,000 m2 space in Berriz (Vizcaya) where our eighth manufacturing plant will be built. This plant will be the site of an assembly area for the new model of machine and the company’s new headquarters. Together with the other seven plants already in existence, which makes over 40,000 m2 available for manufacturing CMZ lathes. CMZ Zaldibar is our first assembly plant with 5,500 m2 of air-conditioned facilities and 150 m2 of cleanroom for precision assemblies. Seuner, the second assembly plant has 10,000 m2 and has been specially designed for assembling large lathes.

Neoprec a plant for machining small and medium-sized parts occupies an air-conditioned surface area of 8,000 m2, with a 500 mm concrete floor that prevents variations in temperature of more than 1ºC in 24 hours. Precitor, a turning and cylindrical grinding plant renovated in 2023, with a in house cleanroom and has 2,000 m2 of air-conditioned surface area. Mecaninor is our plant for machining large parts, fitted with moving column milling machines and bridge grinders in its 4,000 m2 of usable space.

And for industrial boiler-making and sheet metal work, Cafisur in Cádiz has 8,000 m2 of industrial surface area with innovative technology. Finally, Meydi is our electrical assembly plant with 1,250 m2 for cabling and assembling electrical panels.

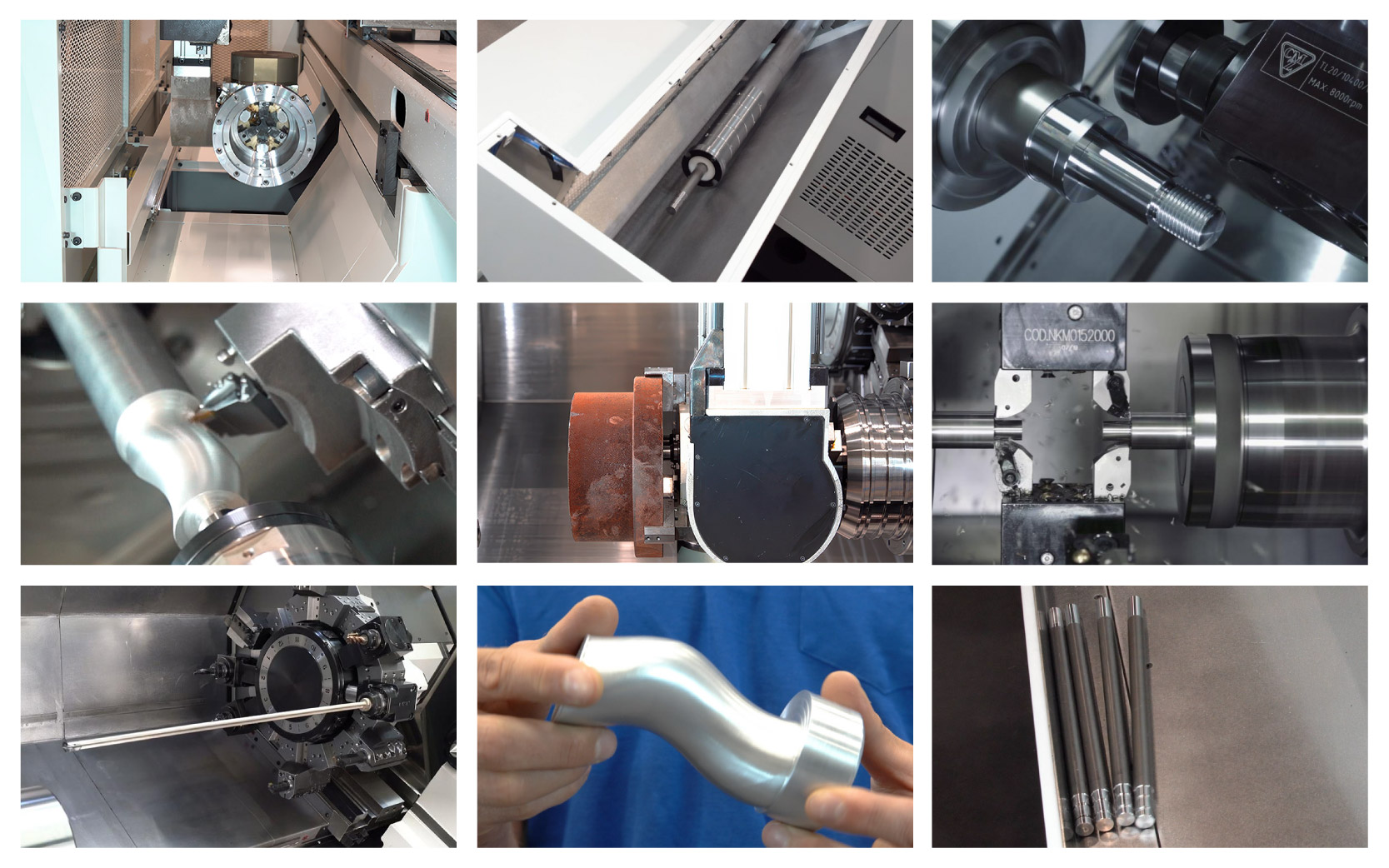

As European manufacturers of CNC lathes, we are committed to the quality and durability of our machines, ensuring a useful life of 20 years. And so, we are committed to manufacturing over 80% of the components for our lathes at our own facilities. This provides us with a high degree of specialisation that differentiates us and makes us competitive.

This integral control has enabled us to optimise and improve the production process over all these years, reducing costs and guaranteeing a top quality product. But the basis for all this are the people: everyone who is part of this project. The value of the human aspect is what has made CMZ what it is today and in 2025, we want to continue to support this.

Our customers place value on the technical content of interest that we share through our media. Aware of how useful it is, our engineering department has worked over these last 365 days to adopt the most innovative applications together with their programming tips. GL 100 (up to 2 x 50 kg parts), mobile tube shaft unloader, eccentric turning… These are some of the applications we launched this year, which help to optimise the operation of CMZ lathes. With an aligned team of people and customer needs always at the centre, sharing knowledge is extremely rewarding.

We ended 2023 with a turnover of €110 M and 549 CMZ lathes delivered. A figure which exceeded the targets marked in the 2021-2023 strategic plan by 10% one year before planned. Faithful to our exporter DNA, 75% of our sales are in foreign countries, thanks to our 6 European subsidiaries and our wide network of distributors.

In addition, according to a report by Empresa XXI, we have consolidated our position as the machine tool company in Vizcaya with the highest sales in 2022. Milestones we achieved thanks to the collaboration of the over 550 people in CMZ who bring a unique human value to each project. The objective is clear: to continue growing sustainably in time and to continue supplying the high market demand for CNC lathes.

Part of the philosophy of in-house production involves manufacturing our own tool holders. To do that, we have three automated cells comprising a five-axis vertical machining centre, a three-dimensional machine for measuring, a washer for cleaning the parts and two robots. This enables us to supply the growing market demand for tool holders.

We also provide access for all users to the CMZ Store, our online shop for tool carriers for CNC lathes. On this online platform you can buy axial, radial, internal and external tool holders and many more accessories with a single click. Its design is 100% tailored to user needs, you can consult the stock in real time wherever you are, guaranteeing dispatch within 24/48 hours.

Month by month we have been publishing various parts that can be manufactured using a CMZ lathe: from such basic items like axles or chess pieces, to watch crowns and dynamometric keys. Over the year we have found out about numerous uses for our machines. Focusing on the world of machine tools from a closer, more human perspective has helped us to connect with our audience, presenting the virtues of manufacturing a European, quality product.

It came to stay, and there have already been four editions of CMZ Magazine, our corporate magazine. Here is where you can find out about the company's latest news first hand and collect the most innovative applications together with their programming tips. The full online version of CMZ Magazine 4 is available now for you to enjoy over this holiday period.

CMZ France was 20 in October, two decades in the field which culminated in an incredibly special three-day event. France is one of the most important markets for us, because since the consolidation of the subsidiary a total of 1,750 CMZ lathes have been delivered there with a total accumulated value of around €180 M. In the sales and after-sales area there are over 25 people in CMZ France and they bought into the project from day one.

Almost 400 people visited the facilities at Vaulx-Milieu. Always bearing in mind the value of the physical, the human aspect, sharing these three days with customers, friends and suppliers made us feel very welcome. It is extremely rewarding to see that 20 years later, we continue with the same enthusiasm as the first day, surrounded by a team that encourages us to improve continuously. .

There are now over 550 of us at CMZ With determination and commitment we are rowing in the same direction and forging ahead with major projects. Corporate growth has been sustained over time, creating a positive social impact in the area. We have talented people who provide a unique value in each idea, each stroke, each campaign and that has enabled us to become what we are today.

In addition, this year we also wanted to encourage imagination, the dream of creating something from nothing. Faithful to our philosophy of in-house production we organised CMZ’s First Children’s Drawing Competition: Paint your Christmas where the youngest in the house have gifted us the most heart-warming and inspiring works of art. Talent must be cultivated and encouraged, and we cannot think of any better way than this.

Let us raise a toast to 2025!