The medical sector plays a crucial role in society by providing healthcare, promoting health, and contributing to the overall well-being of people. Within the medical sector itself, there is an entire industry dedicated to the manufacturing of components that support the development and advancement of healthcare, thereby improving people's quality of life. These industries primarily focus on manufacturing parts and components that are essential for the diagnosis, treatment, and rehabilitation of diseases and injuries.

One of the main reasons why manufacturing components for the medical sector is of utmost importance lies in their contribution to innovation and the development of new medical technologies. Advances in this industry enable the design and production of more sophisticated, precise, and effective medical devices. From joint prostheses and dental implants to specialised surgical tools, each manufactured component is crucial in ensuring patient care.

In recent years, the medical sector has witnessed significant advancements in various areas. The latest technological incorporations range from the use of artificial intelligence and machine learning to enhance diagnostic accuracy, to the use of virtual and augmented reality for patient rehabilitation. Additionally, another challenge faced by the medical sector is the increase in chronic diseases and the aging population. Concepts like the silver economy are already a tangible reality in the market, and the need to meet the demands of this target audience through tailored solutions is something that medical sector companies are already facing.

Furthermore, we are dealing with a market that has very demanding technical requirements and quality standards. Components for the medical sector must comply with rigorous safety and quality standards, as their reliability is crucial for patient safety and well-being. In general terms, these parts must be biocompatible, durable, and functional, and the industry ensures that these requirements are met by using machinery that complies with these technical specifications down to the micron level.

Given this, one type of machinery involved in the manufacturing of components for the medical sector is lathes. In order to ensure quality standards, it is essential to have a fleet of lathes for the medical sector that meet market requirements and enable the production of components with the best possible quality.

Lathes play a crucial role in the medical sector and the manufacturing of components for it. Machining using lathes for the medical sector allows for the production of highly precise, customised, and high-quality components. Moreover, they are machines capable of achieving tight tolerances, complex geometries, and efficient production. This contributes to improving the precision, functionality, and safety of the parts used in the medical sector.

When we talk about components for the medical sector that can be machined on a lathe, the possibilities are endless. Orthopaedic implants (hip prostheses, screws, and nails for surgery...), surgical instruments, medical device components, prosthetics and orthotics, dental implants, brackets, dental tools, diagnostic equipment components...

In general terms, many of the components used in the medical sector are small and compact, as they are often implants or surgical instruments. Compact size is crucial to allow for integration into the human body or manipulation during medical procedures. Moreover, the precision required during their manufacturing is very high, as they are intended for use in medical applications. This makes it of great importance to meet extremely tight tolerances and specifications. For this purpose, it is essential to have lathes for the medical sector that ensure these technical requirements are met.

As mentioned earlier, lathes for the medical sector play a fundamental role in the manufacturing of various components. The use of this type of machinery offers multiple advantages to manufacturers, which are subsequently translated into social benefits. The main advantages are as follows:

Therefore, it can be said that the use of lathes for the medical sector offers significant advantages in terms of precision, efficiency, flexibility, versatility, and process control. This contributes to the manufacturing of high-quality, safe, and reliable medical components.

Below are the most frequent and in-demand processes for the use of lathes for the medical sector.

Joint prostheses are artificial devices or pieces placed in damaged or worn-out areas of the human body, such as the hip, knee, or shoulder, to fulfil their function, i.e., mobility. The elements that make up a joint prosthesis must possess different characteristics. First, biocompatibility is crucial, meaning that the materials used do not cause rejection by the body. Second, they must be strong enough to withstand load and movement without breaking. Finally, they must have a high degree of resistance to friction and corrosion, meaning they can withstand wear and deterioration. In general terms, prosthesis components consist of metallic components, polyethylene components, and fastening elements.

Lathes are essential in the manufacturing and machining of joint prostheses as they can machine parts with curved and precise surfaces, which are necessary for proper articulation. Furthermore, turning and milling operations can be performed on a CMZ lathe, facilitating the production of components in an easy and customized manner. Depending on the size and technical specifications of the prosthesis, a lathe of a specific size may be required. At CMZ, we have a wide range of lathes that can adapt to the needs of each moment, allowing for machining of large or small-sized parts.

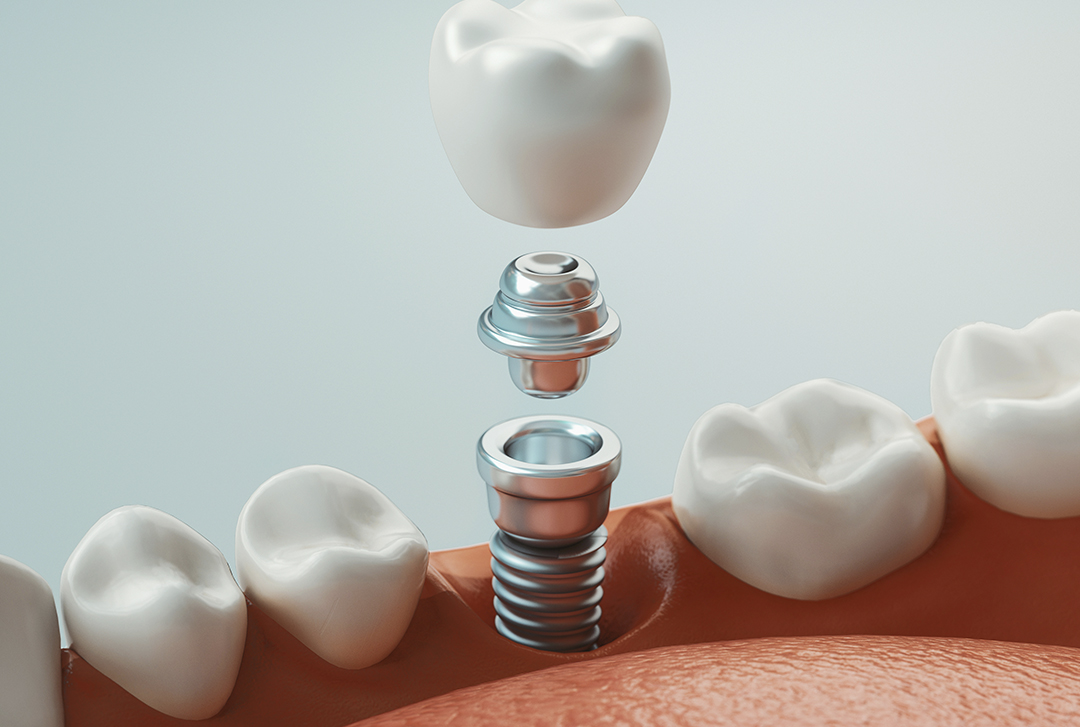

Dental implants are screws, usually made of titanium, implanted in the jawbone to replace the roots of missing teeth and provide support for dental prostheses. When referring to dental implants, we are talking about the entire set composed of the implant itself and the dental prosthesis, which functions as a natural tooth and replicates the appearance of a tooth. In general terms, they consist of a titanium screw, an abutment, and a prosthetic crown.

Lathes play a crucial role in the manufacturing of dental implants as they allow for precise machining of titanium screws and abutments. Since lathes can create high-quality internal and external threads in materials such as titanium, they are the perfect ally for obtaining components that ensure a perfect fit and optimal integration with the patient's bone.

Surgical nails, or intramedullary nails, are devices used to fix and stabilize bone fractures. They consist of a bar or nail, typically made of titanium alloy or steel, which is inserted into the bone, stabilizing it from the inside and keeping the fractured parts in position during the healing process.

The machining of surgical nails plays an important role in their manufacturing process as it allows for precise machining of components with complex shapes. Regardless of the size of the intramedullary nail, lathes can adapt to different technical specifications, creating threads, holes, and even customised shapes in the parts. This ensures precise anatomical adaptation and optimal structural strength.

The manufacturing of medical implants requires the use of moulds that suit the specific design of the implant, whether orthopaedic or dental. These moulds are used to shape and solidify materials, creating three-dimensional structures that mimic the final characteristics of the component. The use of lathes is very common in this process since machining allows for the creation of complex and detailed surfaces that match these final characteristics, which are often very specific. This guarantees faithful replication of designs and the production of high-quality implants.

Medical devices encompass a wide range of instruments and components used in various medical applications, from diagnostic equipment to life support devices. Due to the broad range of components and their different nature, the use of lathes provides great versatility, allowing for the production of highly precise and repeatable parts, regardless of the materials or sizes involved.

In summary, the use of lathes for the medical sector is essential for manufacturing medical components such as joint prostheses, implants, surgical nails, surgical instruments, or moulds for implants, among others. At CMZ, we have a wide range of lathes for the medical sector that adapt to customer requirements, both in terms of required precision and the demanding quality standards imposed by the sector. Discover the wide variety of CNC lathes available now.