Normally several clampings would be needed to finish the parts, or in some cases very specific transfer machines could also be used, but the investment would be much higher. To allow this indexation and be able to machine the part completely in one clamping indexing chucks are the best solution. Not only parts from hydraulic industries can be used, if a part needs to be indexed to be machined an indexing chuck can also be the solution.

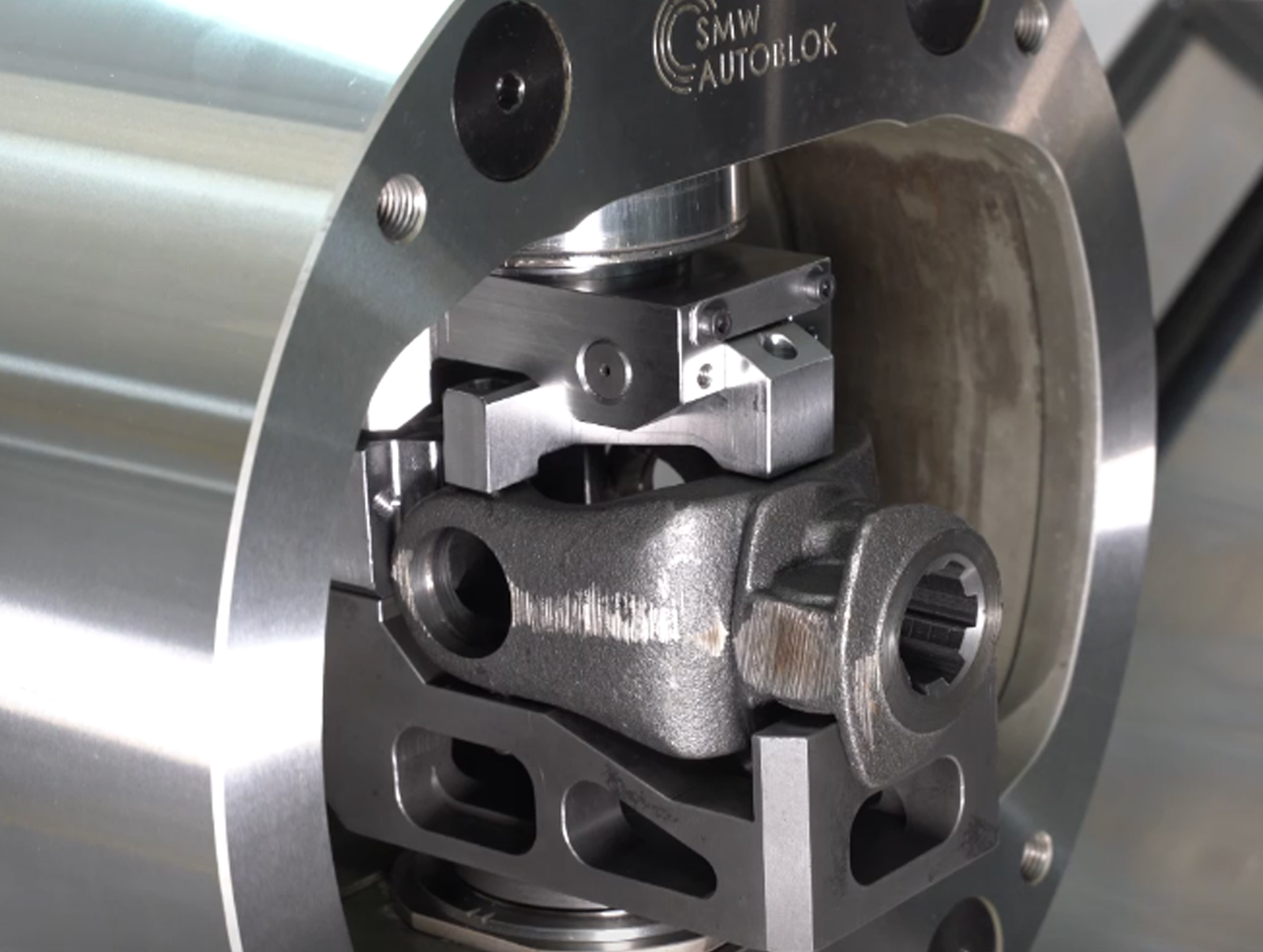

Indexing chucks have an additional axis apart from the rotation of the chuck itself. The orthogonal axis allows the indexation of the part to be machined in different angles. Several chuck designs are possible depending on the angles needed in the parts. Selecting the size of the chuck is also important as the parts needs to be able to index in the internal cavity and also have space for the tools.

In order to lose the least amount of time the indexation can be done while the chuck is rotating, so this will allow to do it in a tool change for example. It is simply programmed by a M code for each angle.

Indexing chucks have two jaws that need to be designed according to the specific part. CMZ has a wide experience designing these kinds of fixtures so do not hesitate in contacting us for further information.

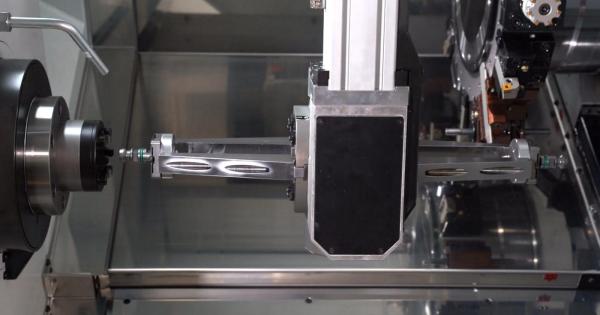

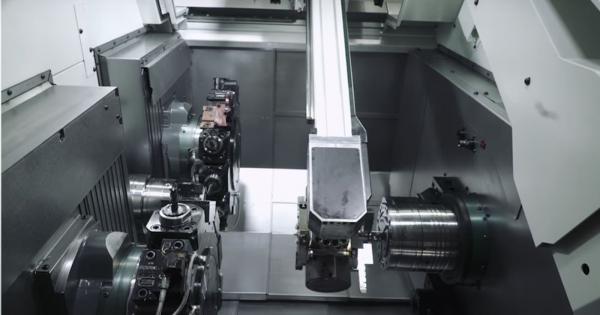

Indexing Chuck are completely compatible with the GL20 automation that CMZ provides so a full automation would be possible as it can be seen in the case of success for our customer La Magdalena.

Discover all the programming tips with this free downloadable

Manufacturing processes usually require different type of machines to finish a component. In order to ease the movement between machines and ensure precision, clamping fixtures can be used. CMZ has developed an automated process to load components mounted in clamping fixtures in a CMZ TA series CNC…

This system is not limited to billets, CMZ manufacture gripper heads and workstockers both for billets and shafts. The combination of a barfeeder and Gantry Loader can be a very effective way to manage larger quantities of finished components. In this video, we show the process of a finished component…

Do you need to automate your production process to reduce idle time and improve yield? CMZ offers various possibilities for automation. The GL 20II Gantry Loader has been designed by CMZ to automate short and long batches and increase the productivity of the CNC lathe. The gripper heads with capacity…

A solution to automate the process of machining shafts in your CNC lathe. Our GL20II gantry loader system combined with the WS700 workstocker for shafts allows you to leave you machines running unmanned. You can have several parts in each line up to 700mm. Controlling the robot is very easy and you…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.