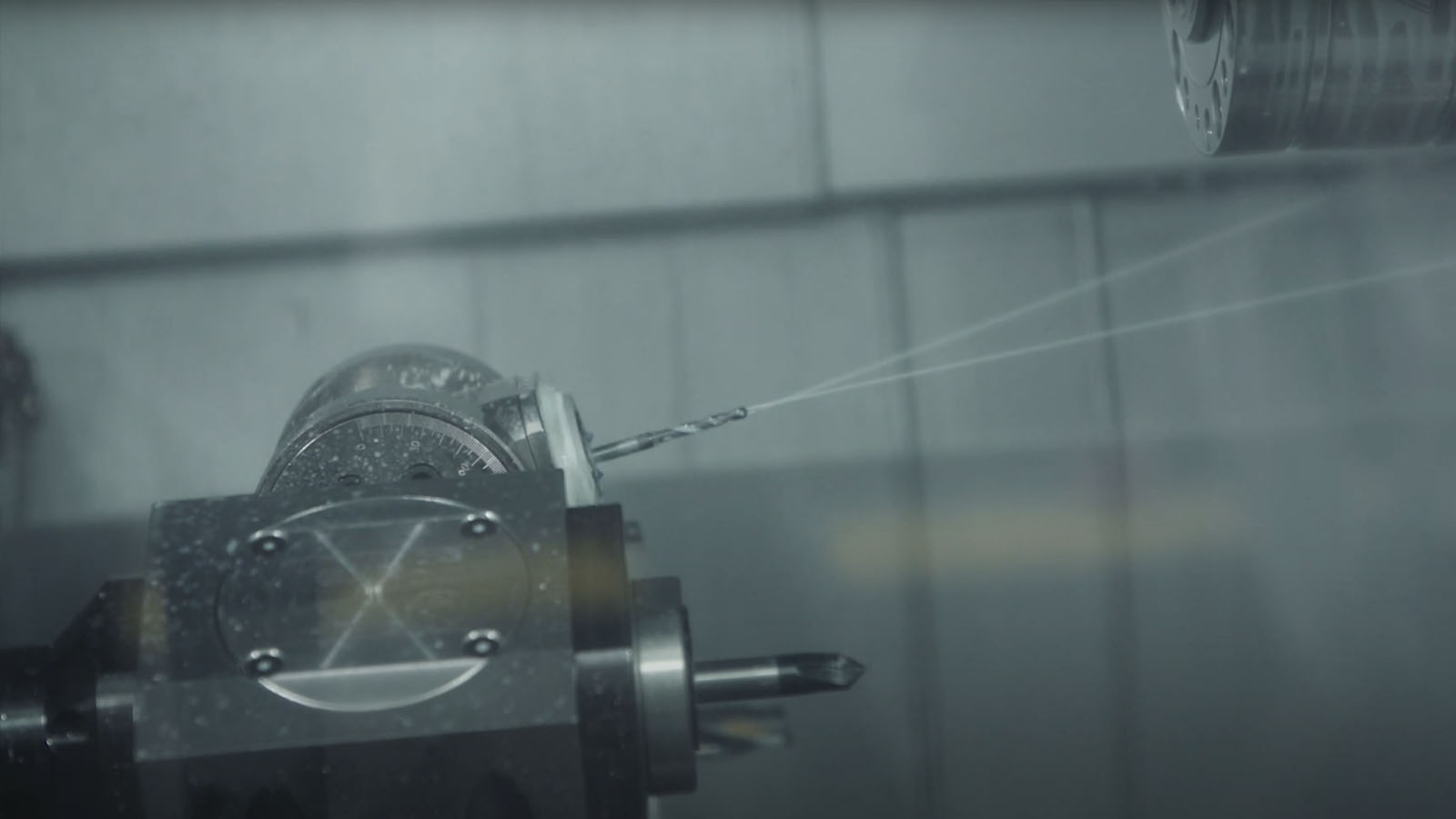

This system gives a pressure up to 70bar, being able to select different pressures by M codes. It uses so called elementless filters that are a hybrid between centrifugal separators and liquid cyclones. This means that the system does not use any paper like other high-pressure systems and can filter up to 10μm. The fact that the filter is "elementless" means that it does not need any maintenance.

The combination of high-pressure coolant and low particle filtration is key in some machining processes such as drilling small holes in difficult materials as it helps with the swarf breakage using through coolant tools.

If your processes do not require high pressure coolant, CMZ can also offer 6, 15 and 35bar coolant options to suit your needs.

Discover all the programming tips with this free downloadable

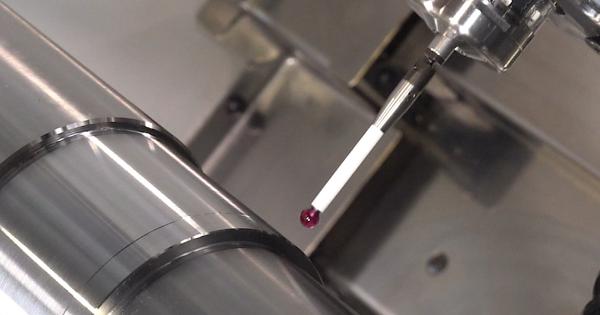

Does your application require in-process measurement? CMZ offers an accessory that can help you with this challenge. This application is usually used in long series runs where the tool wear has to be adjusted without the need of manual input or in critical applications where the tolerances are tight.…

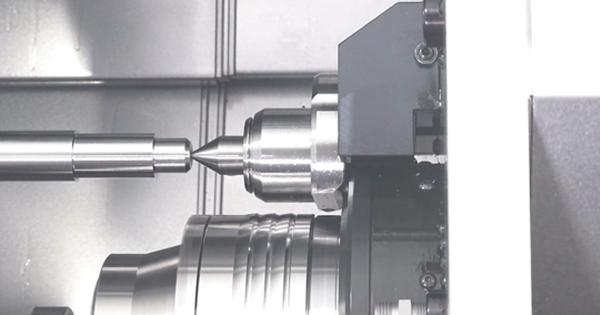

Normally several clampings would be needed to finish the parts, or in some cases very specific transfer machines could also be used, but the investment would be much higher. To allow this indexation and be able to machine the part completely in one clamping indexing chucks are the best solution. Not only…

With this configuration, customers can machine parts in the main-spindle with the tailstock engaged using the upper turret, while simultaneously machining parts in the sub-spindle with the lower turret. Working with a tailstock on a TTL or TTS is a very productive option because of the ability to work…

Measurements during the manufacturing process are required for long machining runs where tool wear must be corrected and compensated during the machining operations. It is also required in order to remove machine's thermal deviations that affect the part dimensionally or to achieve very tight tolerances.…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.