This system is not limited to billets, CMZ manufacture gripper heads and workstockers both for billets and shafts. The combination of a barfeeder and Gantry Loader can be a very effective way to manage larger quantities of finished components.

In this video, we show the process of a finished component made from bar, unloaded from the sub-spindle using a robot while both turrets continue working on the main spindle. The finished part is deposited onto a parts collection table (optional).

If you are interested in learning how we could revolutionise your productivity, get in touch with us now!

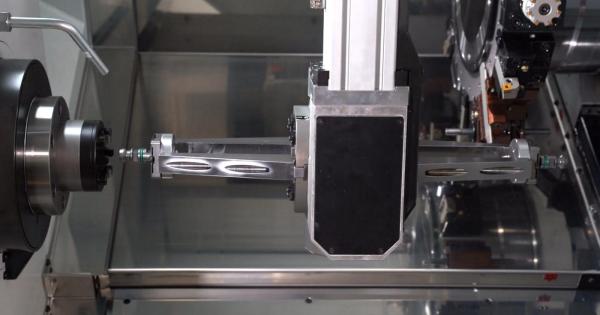

Manufacturing processes usually require different type of machines to finish a component. In order to ease the movement between machines and ensure precision, clamping fixtures can be used. CMZ has developed an automated process to load components mounted in clamping fixtures in a CMZ TA series CNC…

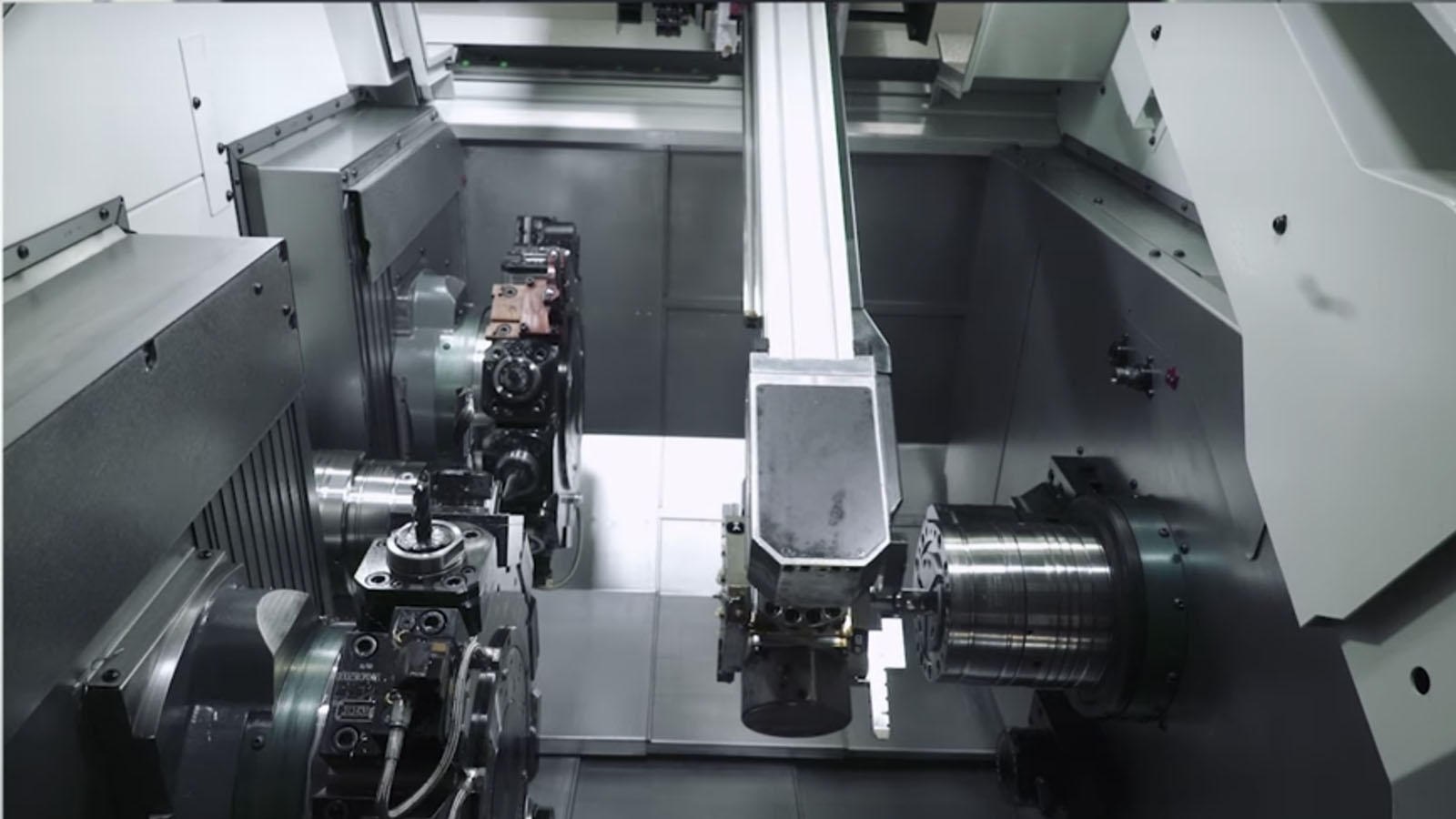

Do you need to automate your production process to reduce idle time and improve yield? CMZ offers various possibilities for automation. The GL 20II Gantry Loader has been designed by CMZ to automate short and long batches and increase the productivity of the CNC lathe. The gripper heads with capacity…

A solution to automate the process of machining shafts in your CNC lathe. Our GL20II gantry loader system combined with the WS700 workstocker for shafts allows you to leave you machines running unmanned. You can have several parts in each line up to 700mm. Controlling the robot is very easy and you…

Normally several clampings would be needed to finish the parts, or in some cases very specific transfer machines could also be used, but the investment would be much higher. To allow this indexation and be able to machine the part completely in one clamping indexing chucks are the best solution. Not only…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.