As in all industries within the automotive sector, quality and precision are key aspects in component manufacturing. One of the fundamental processes to achieve this is machining, and automotive lathes play a crucial role. Vehicles are composed of a wide range of elements such as cylinders, camshafts, gears... CNC lathes can be involved in the manufacturing of all these components. Understanding what types of automotive parts can be produced with lathes is highly useful for optimising the process and taking production to the highest level.

CNC lathes play an essential role in the manufacturing of a wide variety of automotive parts. Pistons, connecting rods, crankshafts, engine blocks, cylinder heads, camshafts...

The possibilities are as varied as they are demanding in terms of precision and quality. Each of these parts serves a specific function in the proper operation of the vehicle. Lathes allow for precise dimensions, complex shapes, and high-quality finishes. Additionally, the efficiency and speed of machining on automotive lathes ensure efficient and cost-effective production of these automotive parts. For these reasons, these machines are perfect allies throughout the process and a guarantee of excellence.

Automotive lathes offer key advantages in the manufacturing of automotive parts. The main advantages are:

These advantages allow for the production of high-quality parts with optimal performance in vehicles. Parts manufactured with automotive lathes are vital components for the engine and other vehicle systems. They contribute to energy efficiency, durability, emissions reduction, and overall performance of the automobile.

The following are the most frequent and in-demand processes for using lathes in the automotive sector.

Cylinder liners are metal tubes inserted into the cylinders of the engine block. Their main function is to provide a resistant and durable working surface for the movement of pistons. Cylinder liners are manufactured using lathes to ensure consistent accuracy and quality in their machining. Lathes allow for the creation of precise and uniform geometry in the cylinder liner, which is crucial for proper sealing between the piston and the cylinder wall, avoiding pressure leaks and loss of performance.

On the other hand, pistons are moving components that travel inside the cylinder liners. They convert the energy generated by fuel combustion into linear motion, which is then transmitted through the connecting rod to the crankshaft. Lathes allow for the machining of the shape and characteristics of pistons with high precision, such as oil drain holes, piston ring grooves, and skirts. This ensures a perfect fit within the cylinder liners and optimal engine performance.

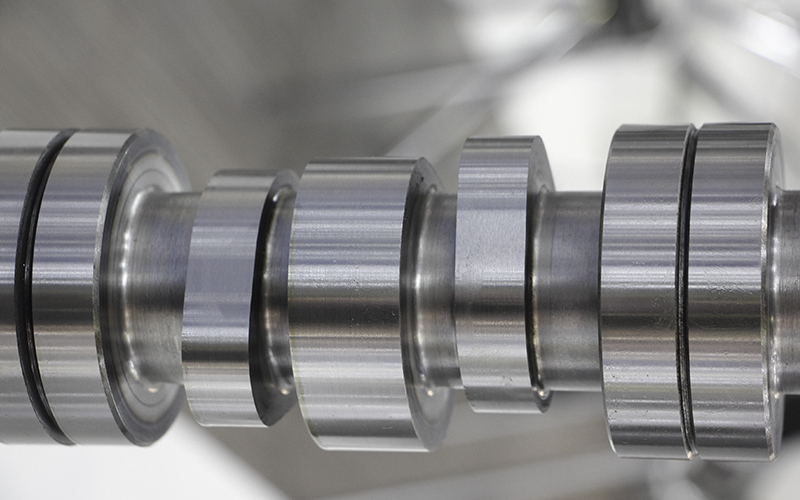

Camshafts allow for the transformation of circular motion into linear motion. A camshaft consists of a shaft on which cams of different shapes and sizes are placed to activate mechanisms such as valves at repetitive intervals. They are cyclic mechanical timers.

In the automotive field, the camshaft is a key component in the engine's distribution system. Its function is to control the opening and closing of intake and exhaust valves. The cams can modify the phase angle to advance and delay the opening and closing of the valves.

The manufacturing of a camshaft requires extreme precision and a series of meticulous steps. The manufacturing process begins with the selection of suitable materials, such as high-strength steel, followed by machining using automotive lathes. These lathes allow for shaping the camshaft, creating the necessary lobes to control the valves. Once machined, the camshaft undergoes heat treatment and polishing processes to improve its strength and surface finish.

In terms of materials, camshafts are usually made of high-strength alloy steels, such as chromium-molybdenum steel. They offer the ideal combination of toughness and fatigue resistance required to withstand high loads and extreme operating conditions in the engine.

Optimal engine performance relies on achieving the precise shape and profiles required. With automotive lathes, it is possible to create the appropriate lobes and ensure the proper functioning of the valves. The CNC technology used in these lathes ensures repeatability and precision in the manufacturing of each camshaft with an extremely high degree of accuracy.

Shafts are essential components in power transmission and motion within an engine. They are structural elements that guide the rotary motion of a part or a set of parts, such as a wheel or a gear. Their manufacturing requires high precision and strength to withstand extreme loads. CNC lathes play a vital role in shaft machining, allowing for the desired dimensions and finishes to be obtained. Automotive shafts can have different shapes and sizes, such as transmission shafts, steering axles, and suspension shafts. Shaft manufacturing involves machining a raw piece of material to obtain the final shape and dimensions. Machining on CNC lathes guarantees accuracy in diameters, thread alignment, and smoothness of the surface of the shaft.

The manufacturing of automotive shafts involves a combination of different operations. The most common ones are milling, grinding, and turning. Turning is the main technique used in shaft machining to obtain the desired shape and dimensions. For this purpose, it is essential to have a range of CNC lathes that meet the required technical specifications.

The strength and durability of automotive shafts are achieved through the proper selection of materials, such as high-strength steels, and precise machining on CNC lathes. The latter allows for the required tolerances to be achieved and ensures the quality and performance of the shafts under extreme operating conditions.

A gear is a type of mechanism that consists of a minimum of two toothed wheels. Its function is to transmit mechanical power from one component to another. When the wheels are of different sizes, the larger one is called the crown gear, and the smaller one is called the pinion gear. The most common gears in automotive applications are spur gears, bevel gears, and planetary gears. Spur gears are used in transmission systems and allow for direct power transfer. Bevel gears are employed in differentials and enable power distribution between the wheels. Planetary gears are used in automatic gearboxes and power steering systems.

Gears are key elements in power transmission and speed changes in a vehicle. Gear manufacturing requires precision in the shape of the teeth and proper meshing between them. Automotive lathes are valuable tools in gear machining, allowing for the desired profiles and tolerances to be obtained. The gear manufacturing process involves the use of milling machines and CNC lathes to cut the teeth and achieve the proper meshing. Additionally, heat treatments are employed to improve the strength and durability of the gears.

The suspensions of a vehicle consist of a set of mechanical elements that connect the wheels to the main structure, facilitating relative movement between them. They have a set of structural elements whose mission is to activate springs and dampers, guiding the wheels in their travel.

Suspension components provide stability and absorb road irregularities, ensuring a safe and comfortable ride.

Among the most relevant suspension components are suspension arms, axle shafts, bushings, shock absorbers, springs, stabilizer bars, and ball joints, among others.

The transmission system of a vehicle transfers the power generated by the engine to the car's wheels, enabling its movement. The main transmission components in the automotive industry are gears, bearings, clutches, driveshafts, synchronizer gears, and universal joints:

Accuracy in the manufacturing of brake components for automotive applications is essential. Safety and quality are at stake at this point. The most common brake components include discs, drums, callipers, brake boosters, and brake lines:

Steering components are key elements for the control and handling of any type of vehicle, allowing the driver to steer it safely and precisely. Their main function is to provide stability, precision, and response in vehicle steering. A steering system in good condition and properly adjusted ensures safe control, avoiding sudden and unpredictable movements that could compromise the safety of the car and its passengers.

The main steering components in automotive applications are:

Lathes are involved in the manufacturing of an immense range of components for various industries, and the automotive industry is a prime example. The interior of a car or a truck is composed of hundreds of components for which different types of machinery, including CNC lathes, are used. CMZ's range of CNC lathes offers machines suitable for machining all types of parts, guaranteeing the precision required in the automotive sector.