The aerospace sector has experienced different phases of growth and slowdown over the years. According to the 'Global Fleet & MRO Market Forecast 2021-2031' report, the global fleet is expected to reach 36,500 aircraft by 2031. Leading aeronautical companies such as Lockheed Martin, Airbus, Raytheon Technologies, Boeing, General Dynamics, Northrop Grumman, BAE Systems, Thales, Safran, and Leonardo SpA focus on innovation for the development of new technologies and solutions in order to create new markets and expand growth opportunities. Regarding aerospace machining in part manufacturing, it still maintains a high degree of craftsmanship in some of its stages. It should be noted that the production series of aircraft usually does not exceed a thousand units. Current manufacturing processes are geared towards more efficient technologies, such as additive manufacturing.

Aerospace machining encompasses a wide range of parts that are essential for the operation of aircraft. These parts require exceptional precision and quality, and lathes provide the capability to manufacture them to the highest standards. Let's take a look at some of the key parts that are machined with lathes for the aerospace sector:

In a production process where every micron matters, equipping oneself with top-level machinery adds immeasurable value to the quality of the final product. CNC lathes are robust, powerful, and reliable machines that allow for the manufacture of parts requiring a high degree of precision. This added value is supported by the following advantages:

The following are the most frequent and in-demand processes for using lathes in the aeronautic sector

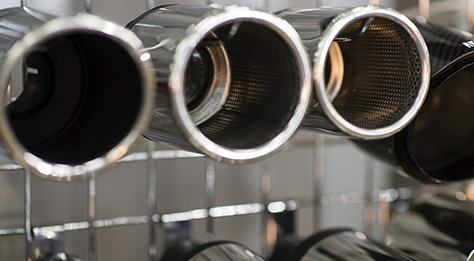

In the aerospace sector, engine components play a crucial role in the operation and performance of aircraft. These parts are responsible for generating the power and propulsion necessary for flight. Here are some specific examples of engine components used in aerospace:

Structural components in aerospace machining are responsible for providing strength, rigidity, and structural support to the aircraft, ensuring its integrity and load-carrying capacity. Here are the main structural components that can be machined using lathes:

Mechanical systems in aerospace ensure the safe and efficient operation of aircraft as they are responsible for controlling and regulating various aspects of flight, such as movement, stability, direction, and other critical functions. Here are some of the most commonly used components:

Connections and fittings ensure the structural integrity, safety, and strength of the aircraft during flight. The most common ones in aerospace include:

The landing gear plays a crucial role in aviation as it determines the safety of takeoff and landing. These components support and guide the aircraft during take-off, landing, and taxiing phases. The main landing gear components are:

Fuel systems provide the necessary fuel supply for the operation of the aircraft's engines, storing, transporting, and distributing fuel safely and efficiently. The most common components are:

Instrumentation plays a fundamental role in aerospace by providing critical information about the status and performance of the aircraft during flight. These systems allow for measurement, control, and visualisation of various parameters such as speed, altitude, temperature, pressure, among others. Some of the components involving lathes in their manufacturing process are:

The strategic advantages of including a significant budget for the purchase of machinery, specifically CNC lathes, are undeniable. Buying lathes for aerospace machining offers numerous advantages, including the following:

Aerospace machining plays a crucial role in manufacturing parts for the aerospace industry. Lathes are essential tools in this process, enabling the production of high-quality, precise, and efficient parts. From engine components to control systems, connections, and fittings, aerospace machining encompasses a wide range of key parts for the aerospace industry. The acquisition of CNC lathes offers numerous strategic advantages, improving competitiveness and adaptability to market demands.