CITIZEN MIYANO ANX 42 VS. CMZ TTS

TECHNICAL SPECIFICATION COMPARISON

-

ANX 42

CNC LATHE WITH TWO TURRETS, BOTH WITH Y AXIS. - Ø46 BAR CAPACITY

- Axes X1, Y1, and X3 connected to the motors via belts

- 6,000 rpm, 20Nm, 2.2 kW driven tools

- Non-integrated driven tool motor

- Spindle power: 11 kW

- Maximum length of part: 130 mm

- The coolant is deposited in the bed

- Maximum coolant pressure: 20 Bar

-

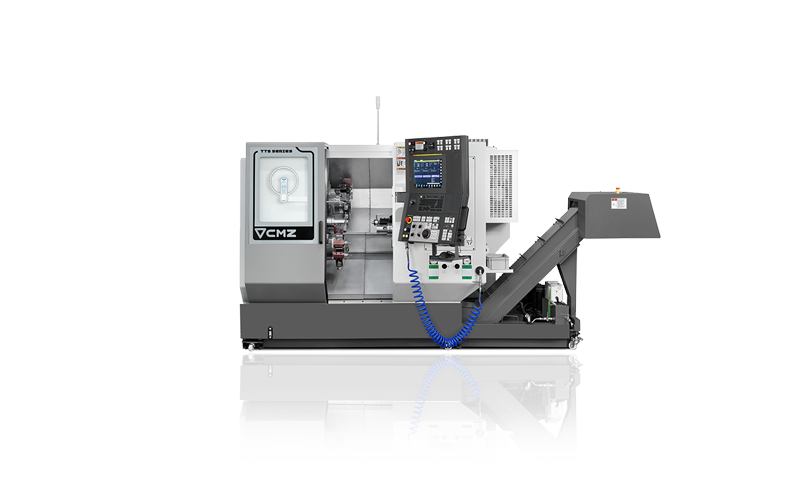

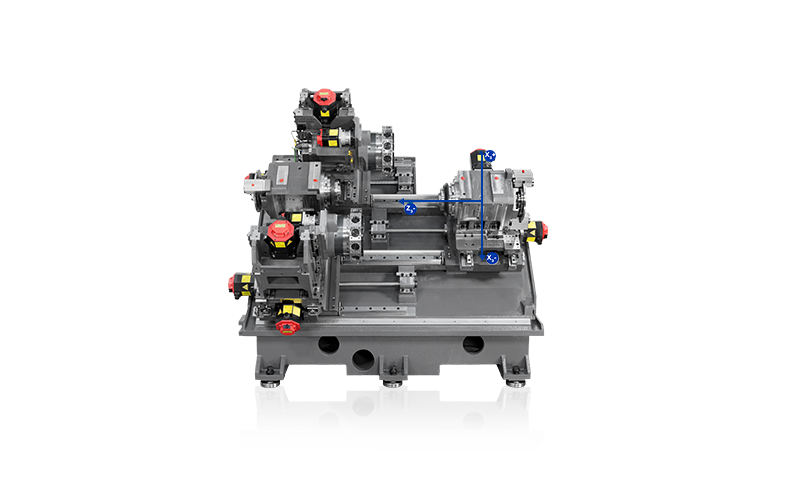

CMZ TTS

ALLOWS SIMPLER CONFIGURATIONS (EVEN WITHOUT DRIVEN TOOLS). - Ø38, Ø46, Ø52 and Ø66 BAR CAPACITY

- All axes directly connected to the motors. No belts

- 12,000 rpm, 26.8 Nm, 13.2 kW driven tools

- Integrated driven tool motor

- Spindle power: 17.2 kW, 66.1 Nm

- Maximum length of part: 160 mm (pickup with catcher box) / 210 mm (pickup with gripper)

- The machine has a coolant tank separate from the machine bed

- Maximum coolant pressure: 70 Bar

CITIZEN MIYANO ANX 42 VS. CMZ TTS

DO YOU WANT TO ACCESS THE FULL TECHNICAL DETAILS?

MULTI-TURRET LATHE FOR BAR TURNING

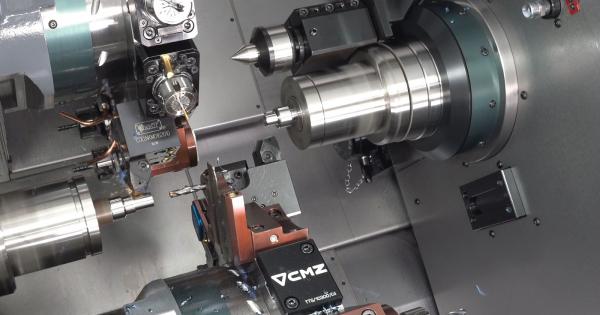

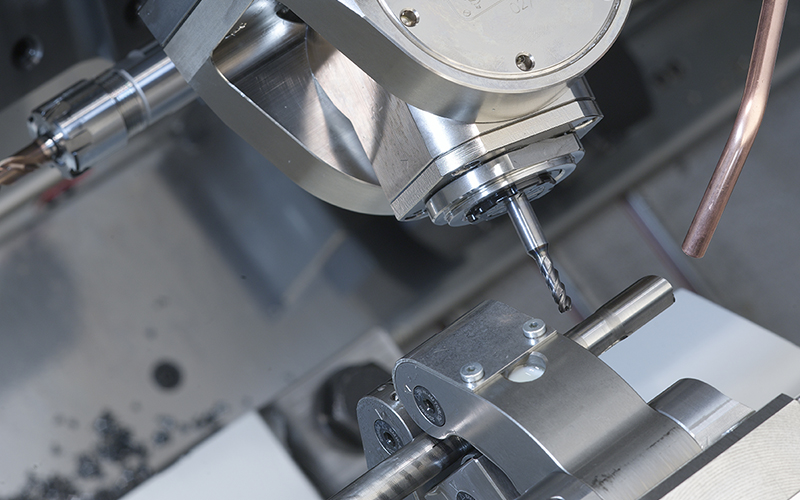

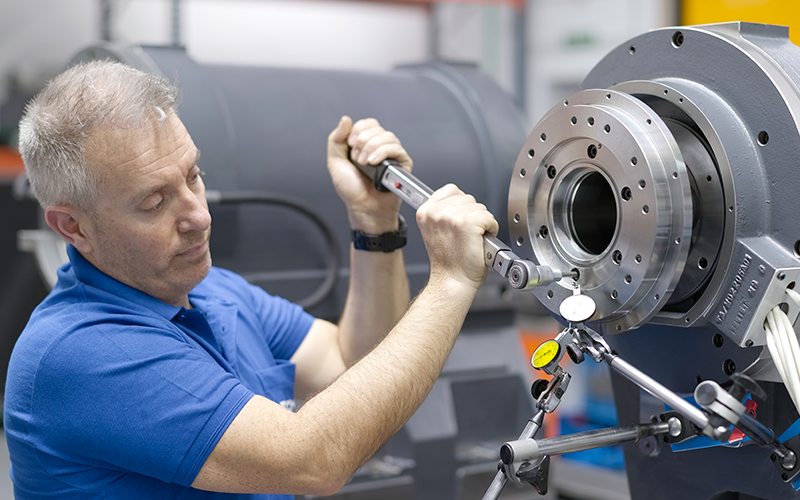

CMZ TTS IN ACTION

GET TO KNOW IN DEPTH ALL THE FUNCTIONALITIES OF THE TTS SERIES

WE ARE CMZ

LEADING EUROPEAN CNC LATHE MANUFACTURER

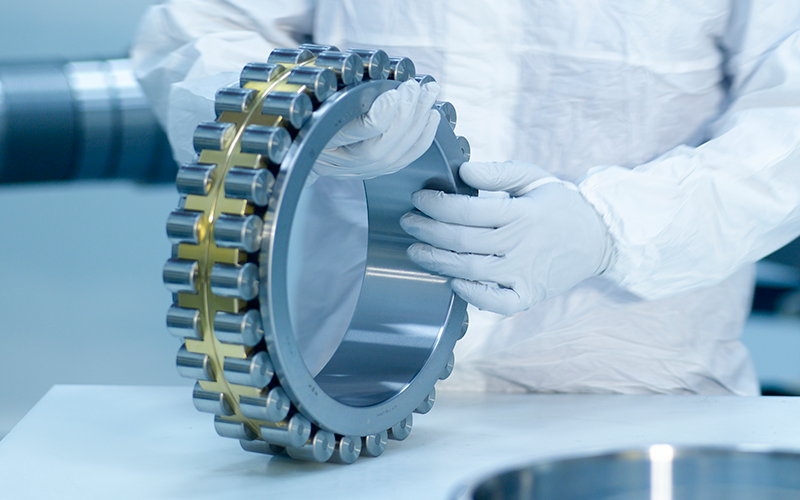

CMZ is a family business with an international dimension and more than 75 years of history. We manufacture the vast majority of the parts that make up our lathes in the more than 32.000 m2 of floor space that compose our manufacturing plants.

Our team of more than 500 people, 5 European subsidiaries and the 11 international distributors, make possible for us to deliver an average of 3 powerful, precise and reliable lathes per day, manufactured with great care at every stage of productive process. Machines with a life cycle of more than 20 years at the service of more than 4.500 customers who are already #turningtheworld with us.

OUR MANUFACTURING PLANTS

THE POWER OF A MANUFACTURER

CENTRAL SERVICES

Zaldibar - Spain

MACHINING PLANT

10.000m2 | Mallabia - Spain

SHEET METAL PLANT

15.000m2 | Cádiz - Spain

ASSEMBLY PLANT

10.000 m2 | Mallabia - Spain

MACHINING PLANT

4.900m2 | Elorrio - Spain

MACHINING PLANT

970m2 | Elorrio - Spain

ASSEMBLY PLANT FOR ELECTRICAL CABINETS

1.250m2 | Zaldibar - Spain