High standards of quality in the machine tool sector mean that manufacturers need precise, reliable machinery. In this context, Bourgogne Precision Mécanique, a company based in Longvic (Côte d'Or, France) decided to include CMZ lathes in its production line years ago. They emphasise the robustness and precision of the lathes and qualities which have lasted over time which mean the machine continues like it did "on the first day".

Although at first we had some doubts about the quality of the machines, because their prices are among the most reasonable on the market, those uncertainties quickly disappeared once we found out what a CMZ machine really is. They are reliable, accurate and trustworthy. CMZ provides features that are different from those of other manufacturers.

NAME: Bourgogne Précision Mécanique

LOCATION: Longvic

ACTIVITY: Precision Machining

MACHINES:

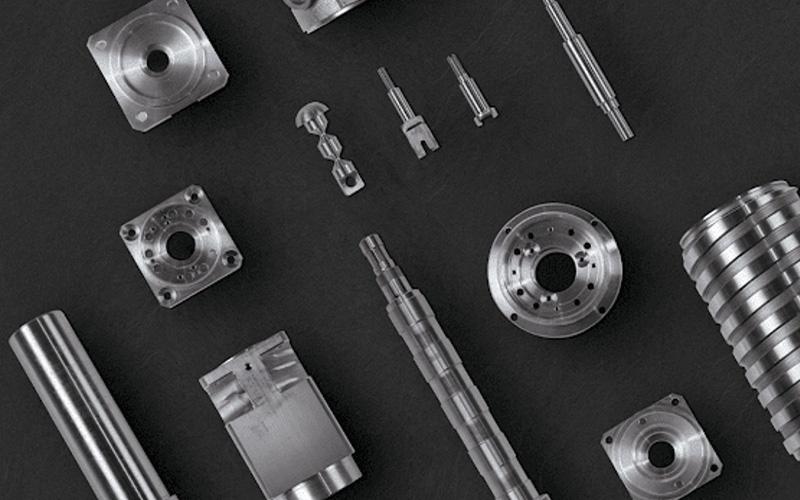

Bourgogne Précision Mécanique (BPM) is a company based in Longvic (France) which arose out of PARKER HANNIFIN a long-standing company specialising in motion and control technologies. Philippe ROUSSEL and Mohamed ENNAIMI, professionals with long experience in parts manufacturing decided, more than 10 years ago, to take over PARKER's production at the Longvic facilities with a few employees. The company's main activity is the production of standard and complex parts for different industries: energy, medical, aeronautics, defence, etc. To that end, they have a fleet of machinery for executing different machining operations like turning, milling and grinding, and the fleet includes two CMZ lathes.

The machine tool sector has undergone many changes in recent decades to which companies like Bourgogne Précision Mécanique have had to adapt. The company identified increased competition in the precision machining business, which brought to the surface the need to stand out in terms of innovation and quality of the manufactured parts. In addition, the projects they were dealing with were becoming increasingly bespoke, as customers were frequently demanding custom parts and so production processes had to be flexible. The investment, in addition to meeting the demands for precision and efficiency had to be scalable in time.

The transformation of the market and the challenges presented required Bourgogne Précision Mécanique to adapt continuously to developments and technology. They were seeking to optimise production costs while maintaining quality and rigorously complying with tight tolerances. Even today, the company machines parts from different materials. From simple metals to metallic compounds that need a versatile and extremely precise machine.

The company heard about CMZ from CMZ France's current sales director, Laurent Loustalot. His passion, the technology and unflagging commitment to the brand impressed them right from the start. In each investment process, Bourgogne Précision Mécanique conducts an in-depth technical study to choose the most appropriate machine. CMZ provided its support from the very beginning with expert technical personnel and ongoing advice.

To make the first investment, they looked not only at the technical documentation and the price, but also at the quality of the technical teams. CMZ makes over 80% of the components for its lathes at its own facilities, and in that way it acquires product know-how and specialisation. For that reason, they did not hesitate to show Bourgogne Précision Mécanique all the details of the machines, which was reassuring and reinforced trust in the company.

Convinced of the quality of the solutions proposed by CMZ, Bourgogne Précision Mécanique decided to invest in the first machine. A decision which, to quote Mr ROUSSEL, they have never regretted.

The first investment in a lathe took place in 2015, with the acquisition of a TC-35-Y-1350, followed years later by a TD-35-Z800. With this equipment the company has completed its technical resources for machining high precision parts. The TD series is made up of prismatic bench lathes with multiple configuration options. Right from the start, CMZ became involved in the project, helping Bourgogne Précision Mécanique to make the most appropriate technical decisions to meet its requirements. Machine commissioning was quick and did not require much after-sales intervention to achieve the desired quality targets.

There are various reasons why BPM chose CMZ. One of the most outstanding characteristics are the robustness and precision of the lathe, qualities which have been confirmed over the years of use. The price is another variable to consider before any purchase. Initially, the company was doubtful about the quality of the machines because the price was among the most reasonable on the market. But those uncertainties disappeared with the use and continuous operation of the machine.

Among the technical characteristics, Bourgogne Précision Mécanique highlights the advantages of the use of the Y-axis and the 12,000 rpm reached by the turret. Thanks to those features, the company has optimised its milling operations. In addition, the robust nature of the CMZ lathes has enabled the production of one-off and mass-produced parts.

Customer satisfaction is a fundamental pillar for CMZ and cases like Bourgogne Précision Mécanique are the ones that can make anyone smile. In their words "you find yourself in front of a group of passionate, honest people who have provided direct technical support. And, the fact that we have our own after-sales service always ready to provide professional support means that BPM recommends CMZ 100%.

LMC opens its doors to tell us about his experience with CMZ cnc lathes. For them, CMZ is not only a machinery supplier, it is a first-class technological partner.

The companies that move the world today started in a garage, in the basement of a house, or... in Steinhagen, in the case of Pentair Jung Pumpen, leading manufacturer of wastewater pumps. As well as their first name, Stefan Sirges and Stefan Sellke also share the same philosophy when it comes to their…

We travelled to Paris to visit the premises of BIC TECHNOLOGIES and meet their Production Manager, Flavien Antz. The visit was exceedingly interesting, and we were able to see first-hand how a world leading company works. They have found the perfect match in CMZ; our company meets all of their needs.…

Christian Meyer is a person who has clear ideas. A man who, like Steve Jobs, started from the garage at home, and has now built a solid company. He considers himself loyal to CMZ's lathes. He is someone who knows how to move in the market and always compares before buying. He describes the difference…