Process automation is crucial to increase productivity. Using bars as stock material is very common in turning world and although the use of barfeeders is extended, the automation gets more complicated when the parts are long because extraction systems are quite costly.

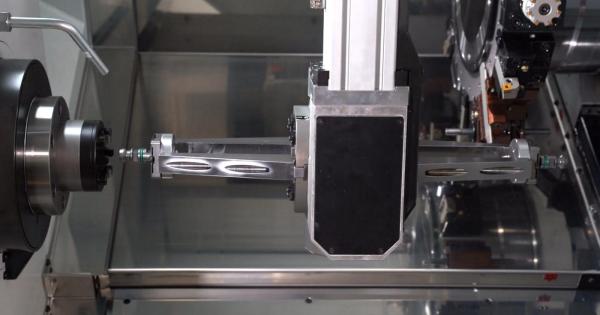

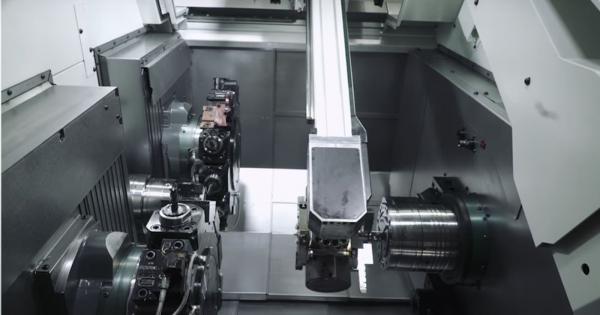

CMZ has pneumatic parts catcher for parts up to 220mm long. In order to offer a solution to unload longer parts CMZ has developed a bar unloader system that can be mounted in machines with subspindle and rear exit chip conveyor, except the TTS where it can be mounted with side exit converyor.

Below is summary of the models where this accessory can be mounted.

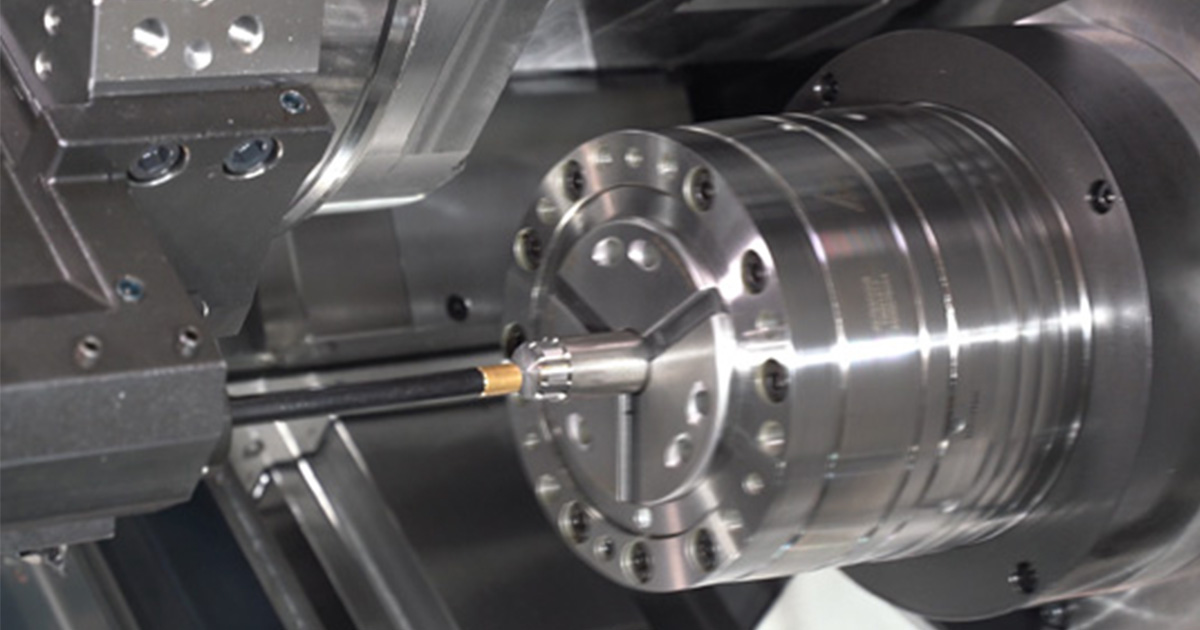

The bar unloader system consists of a static tube that is introduced into the drawtube of the subspindle. During transfer operation the parts are pushed into the tube until they fall into an inclined table. The parts are accumulated in the table until a detector gives the signal that the table is full and the machine stops producing.

Discover all the programming tips with this free downloadable

Manufacturing processes usually require different type of machines to finish a component. In order to ease the movement between machines and ensure precision, clamping fixtures can be used. CMZ has developed an automated process to load components mounted in clamping fixtures in a CMZ TA series CNC…

This system is not limited to billets, CMZ manufacture gripper heads and workstockers both for billets and shafts. The combination of a barfeeder and Gantry Loader can be a very effective way to manage larger quantities of finished components. In this video, we show the process of a finished component…

Do you need to automate your production process to reduce idle time and improve yield? CMZ offers various possibilities for automation. The GL 20II Gantry Loader has been designed by CMZ to automate short and long batches and increase the productivity of the CNC lathe. The gripper heads with capacity…

A solution to automate the process of machining shafts in your CNC lathe. Our GL20II gantry loader system combined with the WS700 workstocker for shafts allows you to leave you machines running unmanned. You can have several parts in each line up to 700mm. Controlling the robot is very easy and you…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.