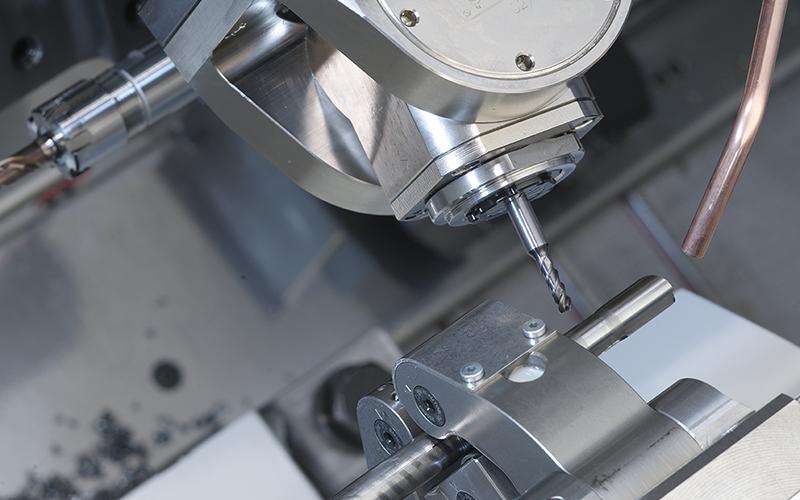

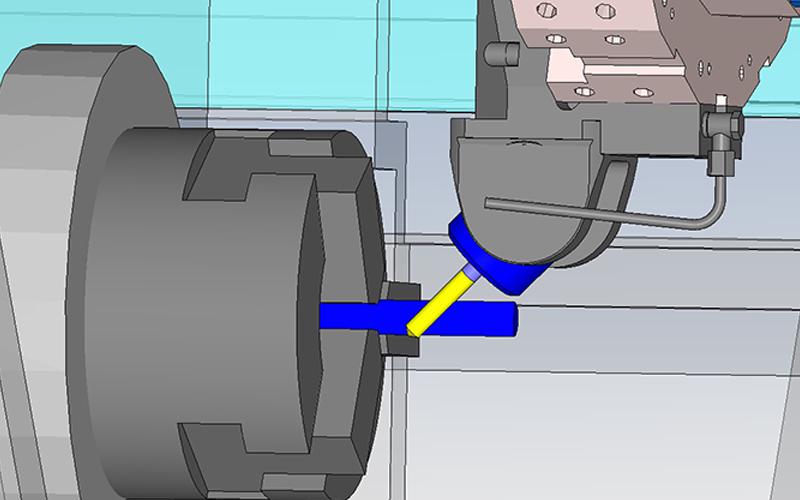

We can often find features in our drawings where an angular machining operation is required. With standard toolholders these features are not achievable because only operations in X and Z directions are possible with standard live toolholders. However, there are some adjustable angle heads in the market that allow you to orient the tool and machine angular features.

Features like coolant or lubrication holes are usually angular to try to get the liquid through the part. With this document CMZ will help you to set up a solution to be able to machine these features.

Discover all the programming tips with this free downloadable

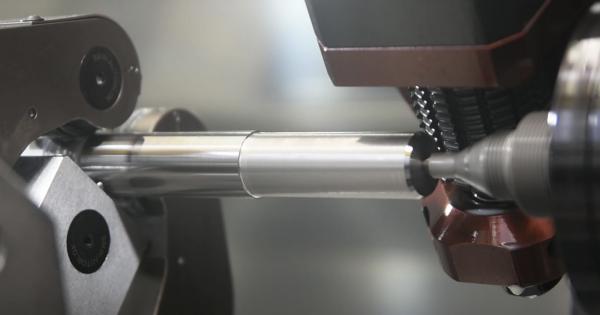

Polygon turning is a process through which flat planes are obtained on the piece through synchronized rotation of the spindle and the live tool. Polygon turning can be performed on our CMZ CNC lathes. It is an alternative process to milling each surface individually. It is more similar to lathing…

The geometry of the gear in the gear hobbing process is obtained by the synchronised movement between the spindle and the live tool. The limit to manufacture gears in a CMZ CNC lathe is around the hob tool being able to produce the required profile but for occasional machining. Bigger gears require…

We would like to welcome helical gear hobbing in a CNC lathe and say goodbye to the dead time that occurs when you have to turn and hob on two different machines. The range of possibilities is very broad since we can hob cylindrical gears with both straight and helical teeth. Technical characteristics…

One of the most critical aspects in many machining processes is chip formation. Long and entangled chips are formed mainly in turning operations due to constant cutting conditions. This issue requires changes in the process; such as modifying machining parameters or changing tools to get into a safer…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.