We are at Neoprec, one of our machining plants where we manufacture small and medium-sized parts. Maintaining a stable temperature is essential for achieving maximum precision in machining because materials like steel expand at approximately eleven microns per degree Celsius to a metre.

For that reason, all our plants have air-conditioning systems to ensure there are no variations in temperature. We have two different types of systems:

Outside the facility are the machines that generate heat and cooling, used to regulate the temperature as needed. In addition, the plant's double walkable roof provides a high degree of thermal insulation. Here we site the air recirculation systems which go to the factory and the ISO Class 8 cleanroom.

These air-conditioning systems provide optimum conditions for delivering extremely accurate results in machining, testing and assembly areas. Find detailed information on the installation and operation of the systems in this video.

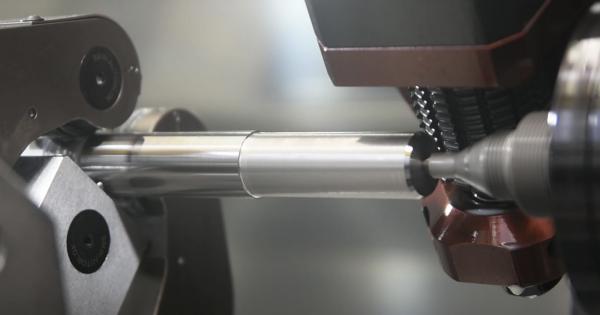

Polygon turning is a process through which flat planes are obtained on the piece through synchronized rotation of the spindle and the live tool. Polygon turning can be performed on our CMZ CNC lathes. It is an alternative process to milling each surface individually. It is more similar to lathing…

The geometry of the gear in the gear hobbing process is obtained by the synchronised movement between the spindle and the live tool. The limit to manufacture gears in a CMZ CNC lathe is around the hob tool being able to produce the required profile but for occasional machining. Bigger gears require…

Usually in components where lubrication or coolant is necessary deep holes can be found in the workpiece to access required positions. The question is often if it is feasible to do it in a CNC lathe. There are machines dedicated to deep hole drilling, but in some cases, they can be done in the same…

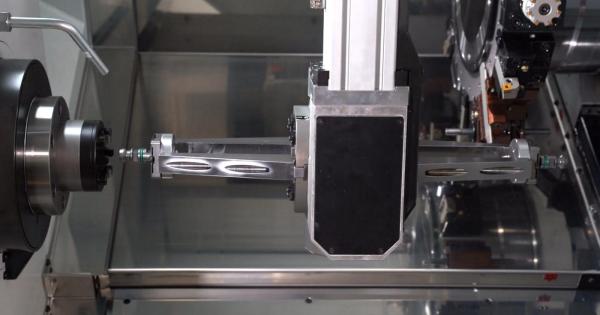

Manufacturing processes usually require different type of machines to finish a component. In order to ease the movement between machines and ensure precision, clamping fixtures can be used. CMZ has developed an automated process to load components mounted in clamping fixtures in a CMZ TA series CNC…

Our applications department can analyse in detail the process to be carried out and offer you a part study helping you to reduce cycle times.